Description

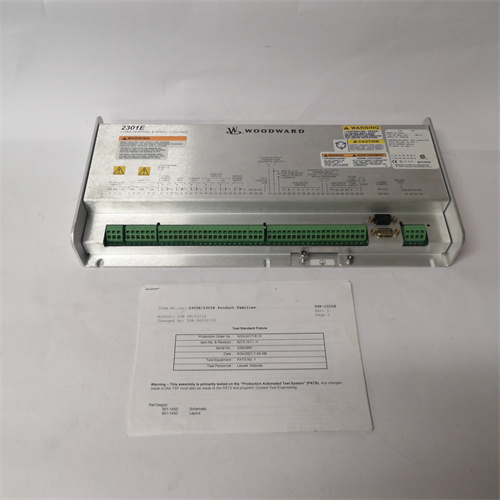

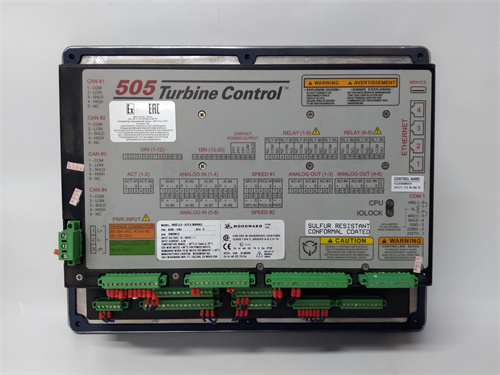

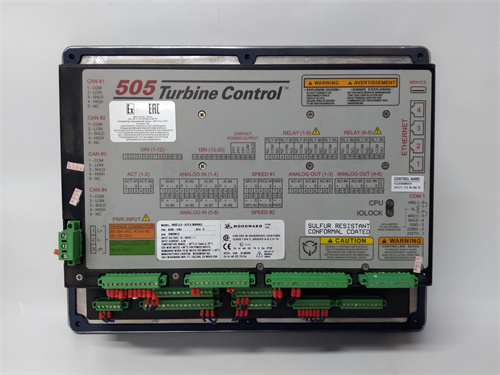

WOODWARD 8200-1302 and 8200-1501

Product Overview

The WOODWARD 8200-1302 and WOODWARD 8200-1501 are advanced programmable logic controllers (PLCs) designed for automation in various industrial applications. These PLCs are part of Woodward’s highly regarded control systems, known for their reliability and efficiency in managing complex processes. The 8200 series enhances operational performance through innovative technology, making them a preferred choice among automation experts.

Product Description

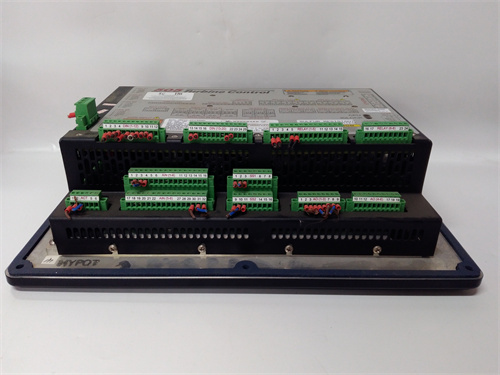

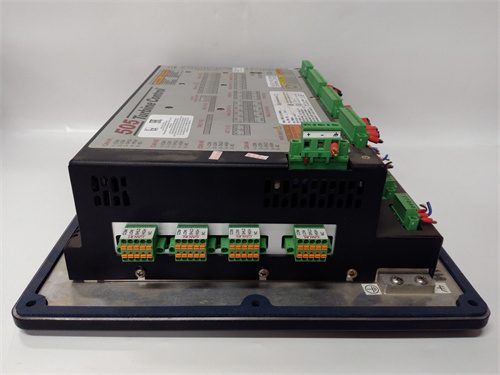

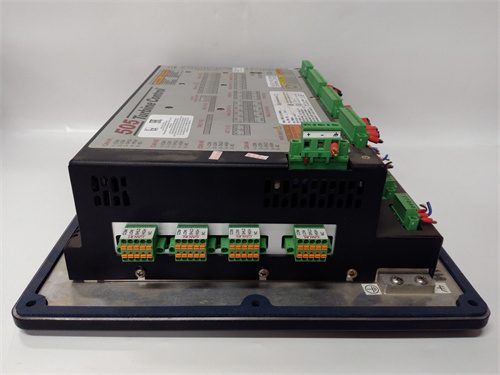

The WOODWARD 8200-1302 and WOODWARD 8200-1501 PLCs exhibit superior functionality tailored for dynamic environments, ensuring seamless integration with various automation systems. The 8200-1302 model specializes in managing critical control functions, offering flexibility and scalability. Meanwhile, the 8200-1501 model is configured for high-speed processing and vast memory capacity, making it ideal for applications demanding rapid data handling and response.

Product Specifications

- WOODWARD 8200-1302

- Input Voltage: 24V DC

- I/O Capacity: Configurable up to 32 digital inputs and 16 outputs

- Communication Ports: RS-232 and RS-485 for enhanced networking

- WOODWARD 8200-1501

- Input Voltage: 48V DC

- I/O Capacity: Up to 64 digital inputs and 32 outputs

- Communication Ports: Ethernet and CAN bus for integration with modern control systems

Advantages and Features

The WOODWARD 8200-1302 and WOODWARD 8200-1501 offer several advantages, including:

- High Reliability: Designed to perform under stringent conditions, ensuring minimal downtime.

- Modular Design: Easily expandable to suit changing operational needs.

- User-Friendly Interface: Intuitive programming environment that simplifies setup and maintenance.

- Versatile Communication Protocols: Compatibility with multiple communication standards enhances system integration.

Application Areas and Case Studies

These PLCs are extensively used in sectors such as:

- Power Generation: For managing turbine control systems and optimizing energy efficiency.

- Manufacturing: Streamlining production lines with precise control over machinery.

- Water Treatment: Monitoring and controlling pumps and other equipment for effective resource management.

A notable application case involved the use of WOODWARD 8200-1501 in a power plant, where it successfully optimized the control of auxiliary systems, leading to a 15% increase in operational efficiency. Conversely, the WOODWARD 8200-1302 facilitated a significant reduction in water treatment facility downtime through enhanced monitoring capabilities.

Competitive Comparison

When comparing WOODWARD 8200-1302 and WOODWARD 8200-1501 to competitors like Siemens S7 and Allen-Bradley ControlLogix, Woodward stands out for:

- Superior Customization: The ability to tailor solutions specifically to client needs.

- Enhanced Support: Comprehensive technical assistance and post-sales service, which are crucial in complex projects.

- Cost-Effectiveness: Competitive pricing without compromising quality, making them accessible for various industrial applications.

Selection Recommendations

When selecting between the WOODWARD 8200-1302 and WOODWARD 8200-1501, consider the following factors:

- Speed and Capacity Needs: Choose the 8200-1501 for high-speed applications requiring vast memory, while the 8200-1302 may be sufficient for standard control applications.

- Integration Requirements: Assess the existing system architecture to determine compatibility with communication protocols and I/O capacity.

Precautions

It is essential to observe the following precautions when implementing the WOODWARD 8200-1302 and WOODWARD 8200-1501:

- Ensure proper electrical connections to avoid damage to the units.

- During installation, adhere to specified environmental conditions to maintain optimal performance.

- Regular monitoring and software updates will help in minimizing operational risks and enhancing functionality.

We are your trusted partner in automation. We provide a wide range of models, including WOODWARD 8200-1302 and WOODWARD 8200-1501, along with sales and technical support for other automation spare parts. We offer special discount prices to serve your needs better. Please contact us, and we will be dedicated to assisting you!

WOODWARD+8200-1302 8200-1501

| DSAI130D ABB PLC |

| ABB 3BSE003127R1 PLC |

| 57160001-ADF |

| 3BSE019216R1 ABB DCS |

| 3BSE018293R1 ABB DCS |

| DSDP150 ABB PLC |

| ABB 57160001-GF PLC |

| DSAI146 DCS |

| SC520 ABB |

| 3BSE003816R1 DCS |

| SC510 ABB DCS |

| AMC-DC DCS |

| ABB 3BSE003832R1 |

| 3ADT309900R1 PLC |

| ABB LDMUI-01 PLC |

| ABB 3BHE005555R0101 PLC |

| NIOC-01C ABB PLC |

| 3ADT309600R1 CPU |

| LDSYN-101 PLC |

| DSTD150A PLC |

| 57160001-UH ABB |

| ABB 3BSE004939R1 CPUPLC |

| 3BSE004940R1 ABB PLC |

| RDCU-02C |

| 57160001-ADK ABB PLC |

| ABB 3ADT220090R0003 PLC |

| UAC389AE01 PLC |

| ABB SDCS-CON-2B PLC |

| UAC389AE01/HIEE300888R0 DCS |

| ABB SDCS-POW-4 PLC |

| 3BSE000860R1 ABB PLC |

| LDSYN-101 PLC |

| APOW-01C PLC |

Email: sales@plcfcs.com

Phone:+86 15343416922

Wechat:+86 15343416922

PLC : Allen Bradley , Siemens MOORE, GE FANUC , Schneider

DCS : ABB ,Honeywell, Invensys Triconex , Foxboro , Ovation,YOKOGAWA, Woodword, HIMA

TSI : Triconex , HIMA , Bently Nevada , ICS Triplex

Complete service we offer

Payment: T/T

Delivery: 1-2 days

Shipment: DHL UPS FedEx, etc

After-sales service: Yes, 24/7 hours

Email: sales@plcfcs.com

Email: sales@plcfcs.com Phone / Wechat:+86 15343416922

Phone / Wechat:+86 15343416922

Wechat:+86 15343416922

Wechat:+86 15343416922