Description

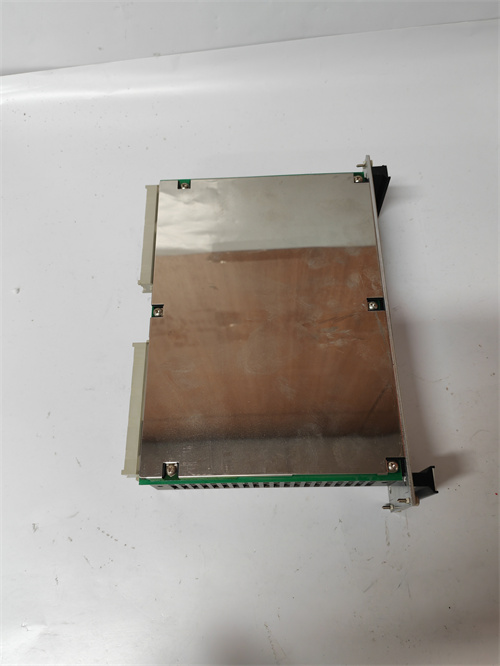

The VIBRO-METER VM600 RPS6U is a high-performance vibration monitoring and protection module. It’s part of the VIBRO-METER product line, which is known for providing advanced condition monitoring solutions for rotating machinery, including turbines, motors, and other critical equipment in industrial and power generation settings.

Product Name:

VIBRO-METER VM600 RPS6U (also known as VM600 RPS6U 200-582-600-013)

Product Description:

The VM600 RPS6U is a specialized vibration protection module used to monitor and protect rotating machinery. It is typically used for high-speed rotating equipment where precise and reliable vibration monitoring is critical for avoiding catastrophic failure and minimizing downtime. The module integrates with a larger VIBRO-METER monitoring system and is designed for a wide range of industrial applications.

Key Features:

- High sensitivity and accuracy for detecting vibration abnormalities.

- Real-time vibration measurement and protection for critical rotating machinery.

- Designed to meet demanding performance standards for machinery protection.

- Modular design that can be easily integrated into existing vibration monitoring systems (VM600 platform).

- Suitable for both continuous monitoring and protective shutdown of machinery based on set thresholds.

- Built-in alarm and shutdown features in case vibration levels exceed predefined limits.

- Compact and robust design, suitable for harsh industrial environments.

Product Parameters and Specifications:

- Input:

- Vibration input: The module supports various types of vibration sensors, typically accelerometers or velocity sensors.

- Signal conditioning: Built-in amplifiers for processing sensor signals to ensure accurate measurement of vibrations.

- Measurement Range:

- Frequency range: Typically 0.1 Hz to 10 kHz, depending on the specific sensor and configuration.

- Acceleration range: Typically up to 100 g for high vibration levels (specific range depends on sensor calibration).

- Velocity range: Usually up to 100 mm/s.

- Output:

- Analog output: Provides continuous analog feedback for vibration levels (e.g., 4-20 mA).

- Digital output: Alarm or shutdown signals if vibration exceeds safe thresholds.

- Protection Features:

- Alarm thresholds: Adjustable threshold settings for various types of faults.

- Shutdown logic: Automatic shutdown of machinery if critical vibration levels are detected.

- Power Supply:

- Supply Voltage: 24V DC (typically, but may vary based on the configuration).

- Power consumption: Low power, suitable for integration in control panels.

- Operating Environment:

- Temperature range: Typically from -20°C to +70°C.

- Enclosure rating: Designed for industrial environments, often with IP67 or IP65 rating depending on configuration.

- Communication and Integration:

- Data communication: Supports industry-standard communication protocols (e.g., Modbus, Profibus, Ethernet).

- Integration with the VIBRO-METER VM600 system for centralized monitoring and data analysis.

- Certifications and Compliance:

- Compliant with various industrial and safety standards (e.g., ISO 10816, IEC standards).

Product Use:

The VM600 RPS6U module is used primarily in industries where the condition of rotating machinery is critical. Applications include:

- Power generation: Monitoring of turbine generators, steam turbines, and gas turbines.

- Oil and gas: For compressors, pumps, and other critical rotating equipment.

- Mining and heavy industries: Monitoring large motors and equipment such as crushers, mills, and conveyors.

- Marine: Used in shipboard turbines, motors, and propulsion systems.

- Manufacturing and manufacturing plants: For critical rotating machinery used in production processes.

Applications:

- Vibration monitoring for early fault detection: Helps in identifying misalignments, imbalance, bearing wear, and other mechanical issues before they lead to failure.

- Machinery protection: Prevents catastrophic damage to equipment by triggering alarms and shutdowns when vibration levels exceed safe operating limits.

- Condition-based maintenance (CBM): Facilitates proactive maintenance schedules by providing accurate data about the health of machinery.

VIBRO-METER+VM600 RPS6U 200-582-600-013

| IC693MDL340 GE |

| IC693MDL940 PLC |

| IC693MDL740 PLCDCS |

| IC693MDL641 PLC |

| IC693MDL655 GE PLC |

| IC693MDL645 GE PLC |

| IC693MDL930 GE PLC |

| GE IC693MDL752 PLC |

| IC693CPU331 PLC |

| IC693CP1364 GE PLC |

| IC693MDL741 GE |

| IC693NTU004 DCS |

| IC693CPU311 GE PC |

| IC693CPU331 PLCPLC |

| IC693CPU364 PLC |

| IC693CP1374 PLC |

| IC693CP1351 PLC |

| IC693CPU350 GE PLC |

| IC670PBI001 GE PLC |

| IC670CHS002 PLC/PC |

| IC670GBI002 GE PLC |

| IC200CPU001 GE PLC |

Email: sales@plcfcs.com

Phone:+86 15343416922

Wechat:+86 15343416922

PLC : Allen Bradley , Siemens MOORE, GE FANUC , Schneider

DCS : ABB ,Honeywell, Invensys Triconex , Foxboro , Ovation,YOKOGAWA, Woodword, HIMA

TSI : Triconex , HIMA , Bently Nevada , ICS Triplex

Complete service we offer

Payment: T/T

Delivery: 1-2 days

Shipment: DHL UPS FedEx, etc

After-sales service: Yes, 24/7 hours

Email: sales@plcfcs.com

Email: sales@plcfcs.com Phone / Wechat:+86 15343416922

Phone / Wechat:+86 15343416922

Wechat:+86 15343416922

Wechat:+86 15343416922