Description

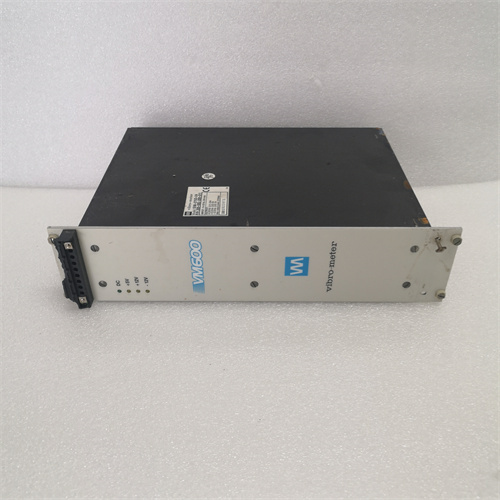

The VIBRO-METER VM600 is an advanced vibration monitoring system designed for industrial applications where monitoring and control of machinery vibrations are critical.

Product Name:

VIBRO-METER VM600 204-040-100-012 Rack

Product Description:

The VIBRO-METER VM600 is a modular vibration monitoring system designed to measure and analyze the vibrations of machinery in various industries. It provides real-time vibration analysis and condition monitoring, enabling early detection of machine faults, thereby preventing unexpected breakdowns and improving maintenance strategies. The system is especially valuable in applications where the reliability and performance of critical machinery are paramount.

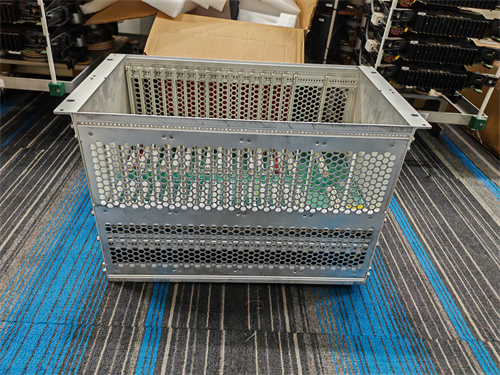

The VM600 204-040-100-012 rack typically refers to the rack-mounted version of this vibration monitoring system, which allows for the installation of multiple modules for monitoring several machines or vibration sensors.

Product Parameters & Specifications:

- Model: VIBRO-METER VM600 204-040-100-012

- Type: Rack-mounted vibration monitoring system

- Rack size: Typically designed for standard 19-inch server racks.

- Number of Channels: Configurable, allowing monitoring of multiple vibration sensors simultaneously (common configurations may support 8, 16, or more channels).

- Measurement Range: Depending on the specific configuration, it can support a wide range of vibration parameters, typically from low-frequency vibrations (e.g., 0.1 Hz) up to several kHz.

- Frequency Response: Typically from DC to several kHz (e.g., 0.1 Hz to 10 kHz).

- Signal Input: Supports various vibration sensors, including accelerometers and proximity probes.

- Output: Digital and/or analog outputs, suitable for connecting to control systems or other monitoring systems.

- Power Supply: Typically 24 VDC (with tolerance depending on the model).

- Communication Interface: Common interfaces include Modbus, Ethernet, and other industrial protocols, allowing for easy integration into SCADA or other monitoring systems.

- Display: Often includes a local display unit for real-time monitoring and diagnostics, but this can vary depending on the specific configuration of the VM600.

- Operating Temperature: Typically -20°C to +60°C, suitable for industrial environments.

- Environmental Protection: Designed for harsh industrial environments (IP rating may vary by model).

Product Use:

The VIBRO-METER VM600 rack system is primarily used for the continuous monitoring of machinery in industries such as:

- Power Generation: To monitor turbines, compressors, and generators.

- Oil & Gas: For monitoring pumps, motors, and compressors.

- Mining & Heavy Industry: Monitoring critical equipment such as crushers, mills, and conveyors.

- Manufacturing: For the condition monitoring of motors, gearboxes, and production lines.

- Aerospace: For monitoring engines and other sensitive equipment.

VIBRO-METER+VM600 204-040-100-012

| IC200ALG240 GE |

| IC200PBI001 GE PLC |

| IC200DBI001 GE PLC |

| IC200GBI001 GE DCS |

| IC200MDL740 GE CPU |

| GE IC200MDL241 PLC |

| IC200MDL940 GE PLC |

| IC200MDL650 GE PLCI/O |

| IC200MDL640 GE |

| A16B-2203-0111 PLC |

| A06B-6097-1205 PLC |

| A06B-6079-H106 GE PLC |

| IC200ALG262J GE CPU |

| IC200MDL640K GE DCS |

| GE IC200ALG240-GC PLCCPU |

| IC200ALG320 GE PLC |

| GE IC20OMDL740J PLC |

| IC693WR330 |

| IC69342G223 PLCCPU |

| IC660BRD021B1 GE PLC |

| GE IC200MDL750H PLC |

| IC200ALG260G GE PLC |

| IC697PFR711 GE PLC |

| GE IC693MDL392B PLC |

| IC693MDL390E GE DCS |

| IC693BEM340 GE PLC |

| GE IC693MDL330 |

| IC693PWR322 GE PLC |

Email: sales@plcfcs.com

Phone:+86 15343416922

Wechat:+86 15343416922

PLC : Allen Bradley , Siemens MOORE, GE FANUC , Schneider

DCS : ABB ,Honeywell, Invensys Triconex , Foxboro , Ovation,YOKOGAWA, Woodword, HIMA

TSI : Triconex , HIMA , Bently Nevada , ICS Triplex

Complete service we offer

Payment: T/T

Delivery: 1-2 days

Shipment: DHL UPS FedEx, etc

After-sales service: Yes, 24/7 hours

Email: sales@plcfcs.com

Email: sales@plcfcs.com Phone / Wechat:+86 15343416922

Phone / Wechat:+86 15343416922

Wechat:+86 15343416922

Wechat:+86 15343416922