Description

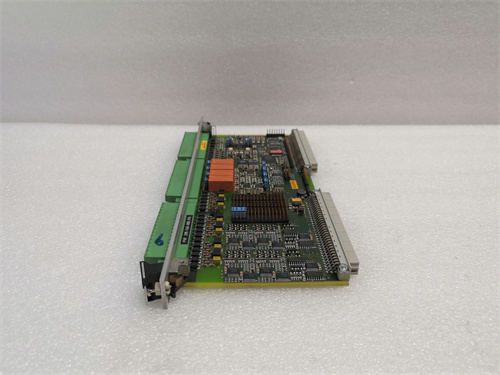

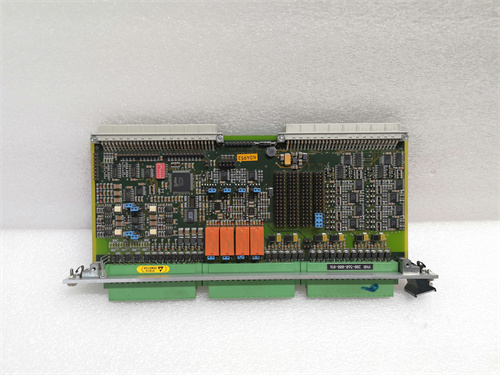

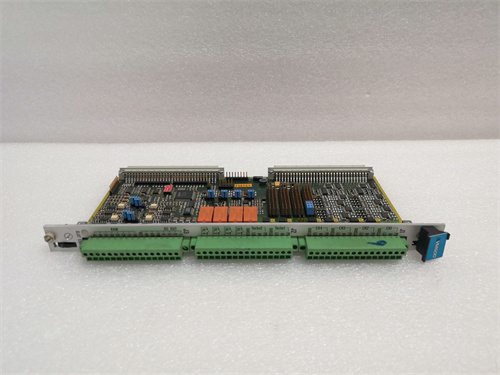

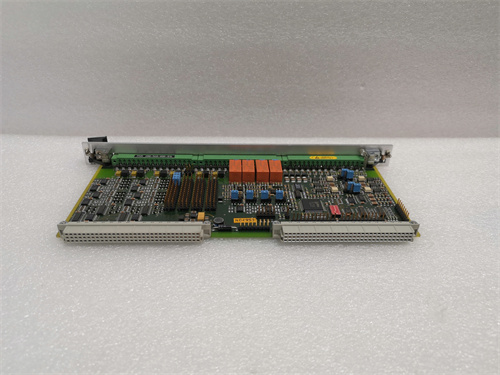

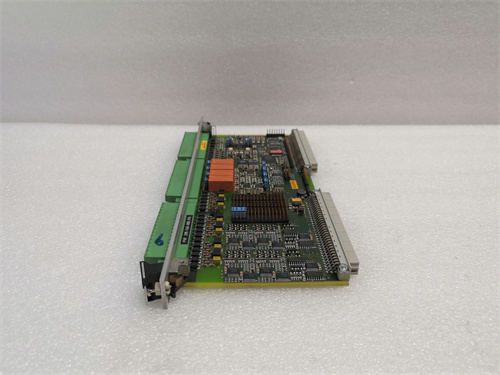

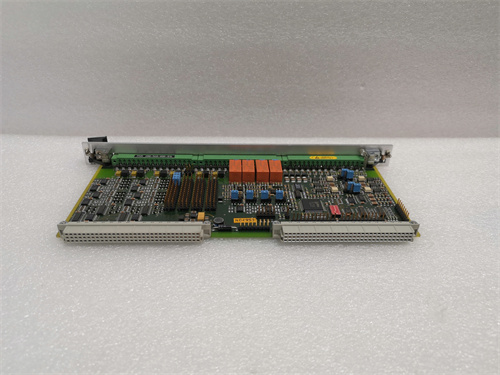

Product Name:

Vibro-Meter+ 200-560-000-016 Module

Product Description:

The Vibro-Meter+ 200-560-000-016 is a vibration monitoring module designed to provide high-precision measurements of vibration levels in industrial applications. This module is often used to monitor the health of rotating machinery and mechanical systems, allowing for early detection of issues such as imbalances, misalignments, or bearing failures. The data provided by the module is typically used for predictive maintenance, improving uptime and preventing costly repairs.

Product Parameters and Specifications:

- Input Range:

- Vibration sensor input (e.g., piezoelectric accelerometers or proximity probes)

- Frequency range typically between 0.1 Hz to 10 kHz or higher (depending on the application)

- Measurement Modes:

- RMS (Root Mean Square) vibration levels

- Peak acceleration

- Velocity or displacement

- Signal Conditioning:

- Amplification and filtering to process vibration signals

- Analog or digital output signals (e.g., 4-20mA, 0-10V, or digital protocols like Modbus or HART)

- Accuracy:

- Typically ±0.1% to ±1% depending on the model and application

- Power Supply:

- Common power requirements range from 12V to 24V DC (some models may support AC input)

- Environmental Conditions:

- Operating temperature range: -20°C to 60°C (or higher, depending on design)

- Humidity tolerance: 0-95% RH, non-condensing

- IP Rating: Often IP65 or higher for industrial environments

- Outputs:

- Analog output (e.g., 4-20mA, 0-10V)

- Digital output (e.g., RS485, Modbus, or Ethernet for integration into SCADA systems)

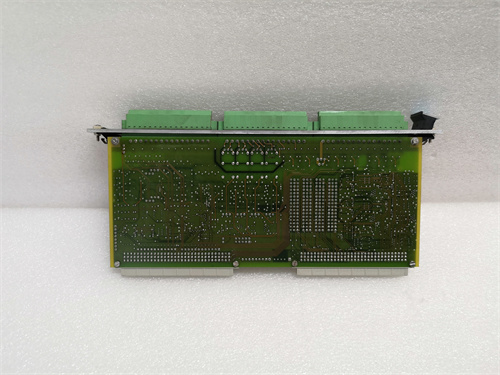

- Size & Mounting:

- Compact form factor for easy integration in control panels or direct mounting on machines

Product Use:

The Vibro-Meter+ 200-560-000-016 module is used in industrial machinery health monitoring systems, often as part of a broader vibration monitoring network. It is primarily used for:

- Predictive Maintenance: Monitoring the vibration of motors, pumps, fans, turbines, compressors, and other rotating equipment to detect abnormal conditions such as misalignment, imbalance, or bearing wear.

- Condition Monitoring: Continuously assessing the operational condition of critical machinery and providing early warning of potential failures to prevent unplanned downtime.

- Asset Management: Helping to optimize the lifecycle and performance of mechanical equipment through continuous data collection and analysis.

- Factory Automation and Process Control: Integrated into SCADA systems to ensure smooth, efficient operations and early identification of performance anomalies.

Vibro-meter+200-560-000-016

| 57C330C |

| JW3250F250A-250-690VAC |

| 6ES7133-1BL11-0XB0 |

| P0922AE |

| MDFKABS090-22 |

| DEIFFAS-113DG |

| 6ES7315-6FF04-0AB0 CPU |

| A02B-0120-C066#TAR |

| MPC240 |

| AKM32C-ANCNR-00 |

| IC698CPE010-JQ |

| EMERSON24263-00 |

| 2711P-B12C4A1 PLC |

| 2080-LC50-24QVB , |

| MPM-B1652F-MJ74AA |

| DSQC688 |

| AX522D2 |

| 171CCC98020 |

| 6ES7414-2XL07-0AB0 |

| 1791-16AC |

| 1769-L30ER |

| 3BHL000391P0101-5SHX1445H0001 PLC |

Brand new✔ In stock ✔ Fast shipping✔

PLC : Allen Bradley , Siemens MOORE, GE FANUC , Schneider

DCS : ABB ,Honeywell, Invensys Triconex , Foxboro , Ovation,YOKOGAWA, Woodword, HIMA

TSI : Triconex , HIMA , Bently Nevada , ICS Triplex

Complete service we offer

Payment: T/T

Delivery: 1-2 days

Shipment: DHL UPS FedEx, etc

After-sales service: Yes, 24/7 hours

Email: sales@plcfcs.com

Phone:+86 15343416922

Wechat:+86 15343416922

PLC : Allen Bradley , Siemens MOORE, GE FANUC , Schneider

DCS : ABB ,Honeywell, Invensys Triconex , Foxboro , Ovation,YOKOGAWA, Woodword, HIMA

TSI : Triconex , HIMA , Bently Nevada , ICS Triplex

Complete service we offer

Payment: T/T

Delivery: 1-2 days

Shipment: DHL UPS FedEx, etc

After-sales service: Yes, 24/7 hours

Email: sales@plcfcs.com

Email: sales@plcfcs.com Phone / Wechat:+86 15343416922

Phone / Wechat:+86 15343416922

Wechat:+86 15343416922

Wechat:+86 15343416922