Description

Product Overview

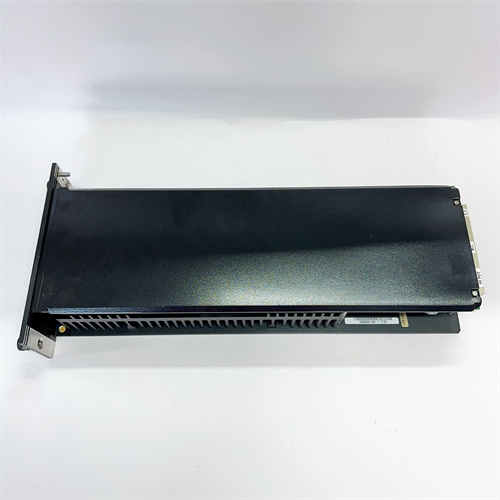

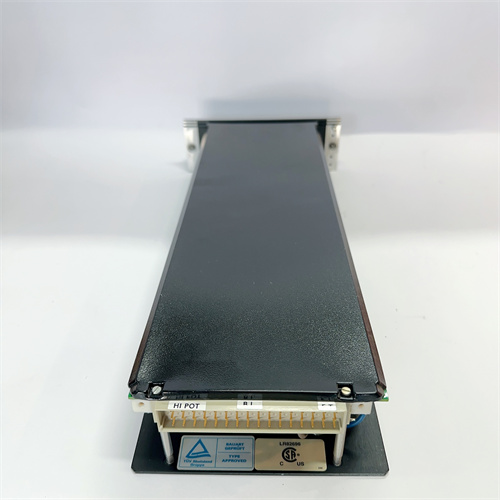

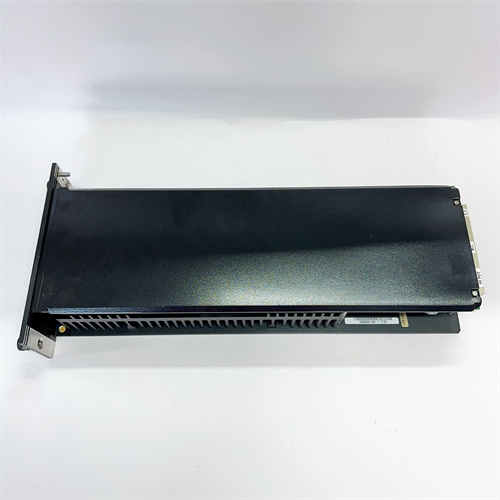

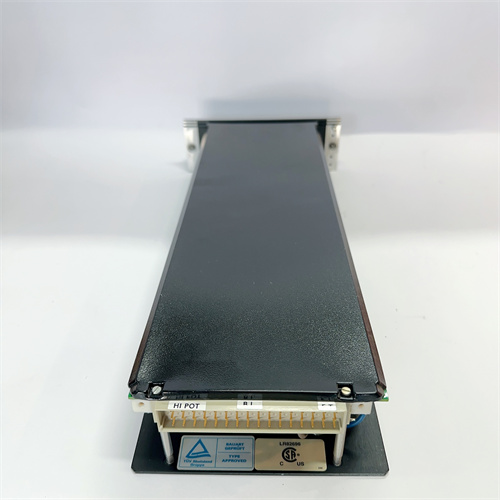

The TRICONEX 8312, 8310, and 8311N are sophisticated and reliable programmable logic controllers (PLC) designed for critical safety and control applications. These models, from the renowned TRICONEX brand, are components in advanced automation systems, offering superior monitoring and control capabilities that enhance operational efficiency and safety.

Product Description

The TRICONEX 8312, 8310, and 8311N PLCs are known for their robust design and exceptional functionality in industrial environments. The 8312 model features advanced redundancy and fault tolerance, ensuring continuous operation even under failure conditions. The 8310 serves as a flexible I/O controller, capable of handling diverse input and output requirements, while the 8311N is equipped for networked communications, providing seamless integration with other control systems.

These products are engineered for high-performance execution of automated tasks, maintaining stringent safety standards across various industries. They are ideal for applications requiring reliable data acquisition, processing, and actuation, delivering precise outcomes and minimizing downtime.

Product Specifications

- TRICONEX 8312:

- Input Voltage: 24 VDC

- Communication Protocols: MODBUS, Ethernet/IP

- Redundancy: Fully redundant architecture

- Dimensions: Compact form factor

- TRICONEX 8310:

- I/O Capacity: Up to 128 I/O points

- Operating Temperature: -20°C to 60°C

- Local Control: Built-in control logic capabilities

- Power Consumption: Low power consumption design

- TRICONEX 8311N:

- Network Interface: Dual Ethernet ports

- Data Rate: Supports high-speed communication

- Security Features: Encrypted communication

- Compatibility: Works well with various legacy systems

Advantages and Features

The TRICONEX 8312, 8310, and 8311N PLCs come with several advantages:

- High Reliability: Engineered for long-term performance with minimal failure risks.

- Scalability: Easily expandable based on operational needs.

- Advanced Safety Functions: Meet stringent safety requirements, suitable for critical applications.

- Versatile Integration: Support various communication protocols for seamless system integration.

These features ensure that users can maintain operational efficiency, improve safety standards, and achieve optimal performance.

Application Fields and Case Studies

The TRICONEX 8312, 8310, and 8311N PLCs are widely utilized across various industries, such as:

- Oil and Gas: For monitoring and controlling drilling and production processes.

- Power Generation: In safety-critical operations of power plants.

- Water and Wastewater Management: For regulating treatment processes and distribution networks.

- Manufacturing: In automation of assembly lines and process control applications.

For instance, in a recent deployment at a natural gas facility, the TRICONEX 8312 effectively managed the safety systems, ensuring continuous and safe operations even during adverse conditions.

Competitive Comparison

When comparing the TRICONEX 8312, 8310, and 8311N to competitors such as Siemens and Allen-Bradley, several distinctions arise:

- Reliability and Safety: TRICONEX products are renowned for their superior fault tolerance, making them a preferred choice for safety-critical environments.

- Flexibility: Unlike many competitors, these models allow users to customize configurations extensively.

- Support and Service: TRICONEX offers robust technical support, often praised for its responsiveness and troubleshooting capabilities.

Selection Recommendations

When selecting a PLC for your automation needs, consider the following recommendations:

- Assess operational requirements—choose the TRICONEX 8312 for high redundancy needs, 8310 for flexibility in control, and 8311N for advanced networking capabilities.

- Ensure compatibility with existing systems, especially when upgrading or expanding operations.

- Evaluate the environment where the PLC will be deployed; the rugged designs of the TRICONEX models make them suitable for challenging industrial conditions.

Precautions

While utilizing the TRICONEX 8312, 8310, and 8311N PLCs, observe the following precautions:

- Regular maintenance checks to ensure system reliability.

- Proper configuration of communication settings to avoid downtime.

- Training personnel adequately on system operation and emergency protocols.

We are your trusted partner, offering a range of products including TRICONEX 8312, 8310, and 8311N along with other automation spare parts and technical support. Enjoy exclusive discount prices; please contact us, and we will be dedicated to serving you.

TRICONEX+8312 8310 8311N

| 07KR228 ABB PLC |

| ABB 07KR264dR1 PLC |

| ABB SIM810 PLC |

| ABB 07KR264b PLC |

| TU812VI ABB PLC |

| ABB TU812VI PLC |

| ABB 07KR220dR1 PLC |

| ABB 07KR220R1 PLC |

| CTB811 ABB I/O |

| ABB CTB811 PLC |

| CTB810 ABB PLC |

| ABB P-HB-IOR-8000N200 PLC |

| ABB PDP80Q PLC |

| PDP800 ABB PLC |

| ABB FAU800 PLC |

| ASM810 ABB PLC |

| 07KT94 ABB I/O |

| ABB DSAI303 PLC |

| ABB DSAI305 PLC |

| DSAO301 ABB PLC |

| ABB P-HB-IOR-8000N200 |

| ABB DSAV110 PLC |

| ABB DSBB170 PLCI/O |

| ABB DSBB175 I/O |

| ABB DSAV111 PLC |

| 07KR240R2 ABB PLC |

| DSBBN001-0 ABB PLC |

| ABB DSBBN002-0 DCS |

| ABB DSBB102 PLC |

| 07KR240bR2 PLC |

| ABB DSBB107 PLC |

| ABB 07KR228R2 PLC |

| DSBB110 ABB |

| ABB 07KT51 PLC |

| 07KR51-A3.6 PLC |

| DSBB110A ABB DCS |

Email: sales@plcfcs.com

Phone:+86 15343416922

Wechat:+86 15343416922

PLC : Allen Bradley , Siemens MOORE, GE FANUC , Schneider

DCS : ABB ,Honeywell, Invensys Triconex , Foxboro , Ovation,YOKOGAWA, Woodword, HIMA

TSI : Triconex , HIMA , Bently Nevada , ICS Triplex

Complete service we offer

Payment: T/T

Delivery: 1-2 days

Shipment: DHL UPS FedEx, etc

After-sales service: Yes, 24/7 hours

Email: sales@plcfcs.com

Email: sales@plcfcs.com Phone / Wechat:+86 15343416922

Phone / Wechat:+86 15343416922

Wechat:+86 15343416922

Wechat:+86 15343416922