Description

Product Name:

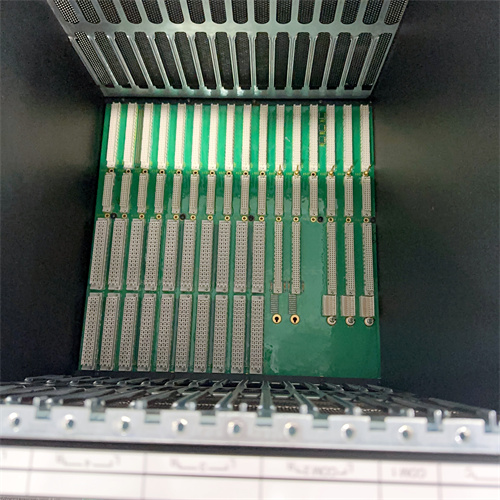

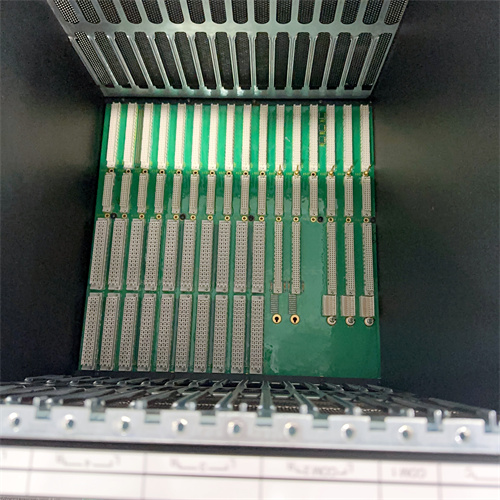

TRICONEX 8120E Safety System Rack

Product Description:

The TRICONEX 8120E rack is a part of the Triconex Safety System, which is an integrated safety solution designed to ensure the protection of critical processes and systems in various industries. The 8120E rack is used to house Triconex safety system components, providing a platform for the installation of processors, power supplies, I/O modules, and communication modules. This rack supports the hardware for a Triconex system that focuses on process safety and fault-tolerant control.

The Triconex 8120E system is widely used in industries such as oil and gas, chemical, power generation, and refining, where high levels of safety and reliability are paramount.

Product Features:

- Redundancy & Fault Tolerance: The Triconex 8120E rack supports redundant configurations for critical components, ensuring system integrity even in the event of a failure.

- Scalability: Can support a range of I/O modules, allowing flexibility for different process control and safety requirements.

- Modular Architecture: Allows easy replacement or upgrade of system components without disrupting the entire system.

- High Availability: Designed for continuous operation in safety-critical applications with minimal downtime.

- Integrated Diagnostics: Includes diagnostic tools that help monitor system performance and identify potential issues early.

Product Parameters and Specifications

- Rack Form Factor:

- 19-inch standard rack-mounted chassis for easy integration into existing control panel setups.

- Power Supply:

- Powered by redundant power supply units (PSU) ensuring reliable operation.

- DC voltage input (typically 24 V DC).

- Capacity:

- Can house up to 10 I/O modules and 1 or 2 processors depending on configuration.

- Supports up to 128 points of I/O (depending on the module configuration).

- Processor Options:

- The system supports high-performance processors like the Tricon processor and Tricon CX, capable of performing complex safety-critical tasks.

- Input/Output Modules:

- Supports a wide variety of I/O modules, including analog, digital, and safety I/O modules.

- Supports up to 10 input/output modules per rack, depending on configuration.

- Communication:

- Includes communication ports for connecting with other Triconex systems, including support for Modbus, Ethernet, and proprietary Triconex communication protocols.

- System Diagnostics:

- Built-in diagnostic LEDs and tools for fault detection, operational status, and configuration validation.

- Temperature and Environment:

- Operational temperature range: 0°C to 60°C (32°F to 140°F).

- Relative Humidity: 5% to 95% (non-condensing).

- Designed for harsh industrial environments.

- Safety Certification:

- Certified to meet IEC 61508 functional safety standards (SIL 3).

- Compliant with international safety standards such as ISA 84, IEC 61511, and ISO 13849 for safety-critical systems.

- System Expansion:

- Additional racks and modules can be integrated into larger Triconex safety systems to support complex safety functions across large-scale facilities.

Product Use

The TRICONEX 8120E rack is primarily used in industries that require high availability and reliability for safety-critical systems. Common applications include:

- Process Safety Systems (SIS):

- Protecting industrial processes from unsafe conditions by detecting and mitigating hazards such as high pressure, temperature, or toxic gas concentrations.

- Emergency Shutdown Systems (ESD):

- Automatically shutting down processes in response to a detected fault or dangerous condition to prevent accidents, explosions, or environmental damage.

- Fire and Gas Detection Systems:

- Monitoring critical process areas for fire or gas leaks, and triggering alarms or shutdowns when necessary.

- Safety Instrumented Systems (SIS):

- The 8120E rack supports the implementation of SIS that meet the highest safety integrity levels (SIL 3) required in industries like oil & gas, chemical processing, and nuclear power.

- High-Risk Industries:

- Power plants, refineries, petrochemical plants, and mining operations, where the potential consequences of equipment failure could be catastrophic.

TRICONEX+8120E

| SD834 3BSC610067R1 ABB PLC |

| ABB 3BSC610067R1 DCS |

| SD834 ABB PLC |

| ABB TU833V1 |

| 3BSE038726R1 ABB PLC |

| TB825 3BSE036634R1 PLC |

| ABB 3BSE036634R1 |

| TB825 ABB |

| ABB TB806 3BSE008536R1 |

| 3BSE008536R1 ABB DCS |

| IB806 ABB PLC |

| ABB TK801V012 PLC |

| 3BSC950089R3 ABB |

| ABB SD833 3BSC610066R1 PLC |

| 3BSC610066R1 ABB DCS |

| SD833 DCS |

| TB807 3BSE008538R1 ABB PLC |

| ABB 3BSE008538R1 |

| TB80Z ABB PLC |

| TB805 3BSE008534R1 DCS |

| 3BSE008534R1 PLC |

| IB805 PLC |

| TK801V006 ABB |

| 3BSC950089R2 ABB |

| ABB SS832 3BSC610068R1 PLCDCS |

| 3BSC610068R1 ABB |

| ABB SS832 |

| CI830 3BSE021480R1 PLC |

| 3BSE021480R1 ABB CPUPLC |

| CI830 ABB I/O |

| AI835A 3BSE051306R1 ABB CPU |

| ABB 3BSE051306R1 |

Email: sales@plcfcs.com

Phone:+86 15343416922

Wechat:+86 15343416922

PLC : Allen Bradley , Siemens MOORE, GE FANUC , Schneider

DCS : ABB ,Honeywell, Invensys Triconex , Foxboro , Ovation,YOKOGAWA, Woodword, HIMA

TSI : Triconex , HIMA , Bently Nevada , ICS Triplex

Complete service we offer

Payment: T/T

Delivery: 1-2 days

Shipment: DHL UPS FedEx, etc

After-sales service: Yes, 24/7 hours

Email: sales@plcfcs.com

Email: sales@plcfcs.com Phone / Wechat:+86 15343416922

Phone / Wechat:+86 15343416922

Wechat:+86 15343416922

Wechat:+86 15343416922