Description

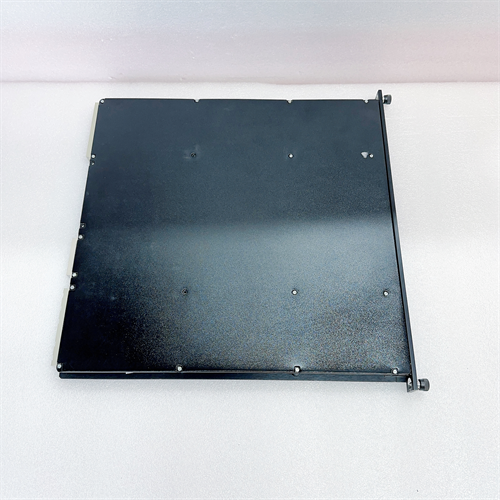

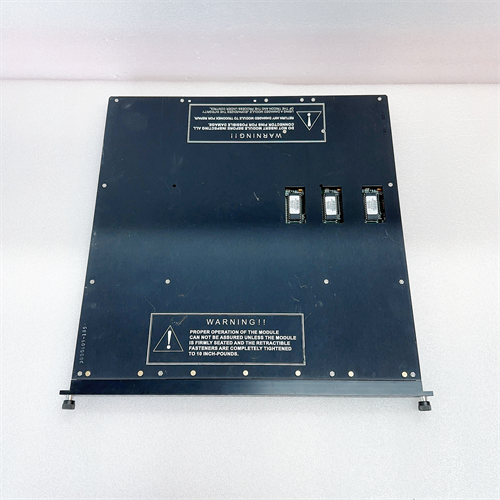

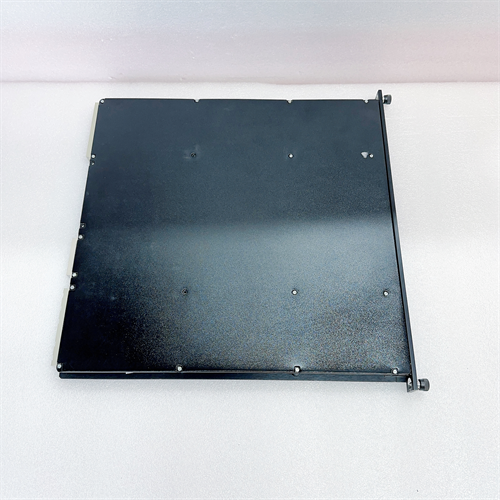

The TRICONEX 3623T is a module from the TRICONEX safety system product line, specifically designed for use in high-integrity and mission-critical applications such as process automation, safety instrumented systems (SIS)

Product Name:

TRICONEX 3623T – Safety I/O Module

Product Description:

The TRICONEX 3623T module is part of the Tricon™ Safety System, which is a highly reliable, fault-tolerant system used in various industries like oil and gas, chemical processing, power generation, and more. The TRICONEX 3623T is typically used as an input/output module that integrates with the Tricon system for safety applications, monitoring and controlling critical parameters in process systems.

The module is designed to operate within the high standards required for safety and reliability, delivering real-time data and ensuring that systems maintain integrity during fault conditions or abnormal events.

Product Parameters and Specifications:

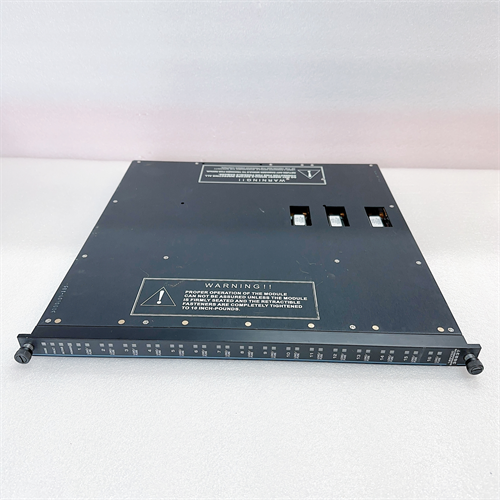

- Module Type: Safety I/O (Input/Output) Module

- Compatibility: Part of the Tricon™ Safety System (typically integrated with Triconex controllers)

- Function: Used for receiving input signals (e.g., from sensors or switches) and transmitting output signals (e.g., to actuators) while ensuring system integrity and meeting safety requirements

- I/O Channels: Generally supports a number of digital or analog input/output channels (typically 16-32 I/O per module)

- Input Types: Digital (dry contact, 24V DC) or Analog (4-20 mA, 0-10V)

- Output Types: Digital relay outputs, 4-20 mA, or discrete relay contacts

- Power Supply: Typically powered via a backplane or external DC supply (24V DC)

- Redundancy: High-availability features (e.g., redundancy with other modules or controllers)

- Environmental Ratings: Suitable for industrial environments (temperature range, humidity, etc.)

- Safety Certifications: Compliance with major international safety standards (such as IEC 61508, ISO 13849, SIL2/3)

Product Use:

The TRICONEX 3623T is primarily used in safety-critical applications across various industries where process systems need to meet functional safety standards. Some examples include:

- Oil & Gas: To ensure the safe shutdown of systems in case of hazardous conditions, like overpressure or temperature fluctuations in critical assets (pumps, compressors, etc.).

- Chemical Processing: Monitoring and controlling chemical reactions, pressure, flow, and temperature in pipelines and reactors, ensuring a safe operating environment.

- Power Generation: Used for protecting electrical equipment and maintaining operational safety in power plants, such as turbine control, generator protection, and emergency shutdown systems.

- Manufacturing & Utilities: Helps maintain system safety in processes that require high uptime and fault tolerance, like critical manufacturing or utility infrastructure systems.

The module’s robust design ensures it functions even in challenging environments and contributes to the overall safety integrity level (SIL) of the system in which it operates.

TRICONEX+3623T

| IC697MDL250 GE DCS |

| IC697MDL350 GE DCS |

| GE IC697MDL650 DCS |

| IC697MDL740 GE DCS |

| IC697MDL750 GE DCS |

| IC693ALG392 GE DCS |

| GE IC3000CS200M DCS |

| IC3693ALG220 GE DCS |

| IC670ALG310 GE |

| GE IC670CHS002Z DCS |

| IC670PBI001-BE GE |

| IC693ALG223 GE DCS |

| IC693ALG390D GE |

| IC693BEM331K GE DCS |

| IC695CP1315 GE DCS |

| GE IC693CPU350 |

| IC693CPU364 GE DCS |

| GE IC693DSM302 |

| GE IC693PBS201 DCSPLC |

| GE IC693PWR321 PLC |

| IC695CPU310-GV GE DCS |

| IC697ALG320 GE DCS |

| IC697CP1782 GE PLC |

| IC697MDL653 GE DCS |

| IS415UCVGH1A GE CPU |

| DS2O0DPCBG1AAA GE PLC |

| DS200PCCAG6ACB GE PLC |

| GE DS200GDPAG1AFB PLCDCS |

| GE DS215TCCBG8BZZ01A PLCDCS |

Email: sales@plcfcs.com

Phone:+86 15343416922

Wechat:+86 15343416922

PLC : Allen Bradley , Siemens MOORE, GE FANUC , Schneider

DCS : ABB ,Honeywell, Invensys Triconex , Foxboro , Ovation,YOKOGAWA, Woodword, HIMA

TSI : Triconex , HIMA , Bently Nevada , ICS Triplex

Complete service we offer

Payment: T/T

Delivery: 1-2 days

Shipment: DHL UPS FedEx, etc

After-sales service: Yes, 24/7 hours

Email: sales@plcfcs.com

Email: sales@plcfcs.com Phone / Wechat:+86 15343416922

Phone / Wechat:+86 15343416922

Wechat:+86 15343416922

Wechat:+86 15343416922