Description

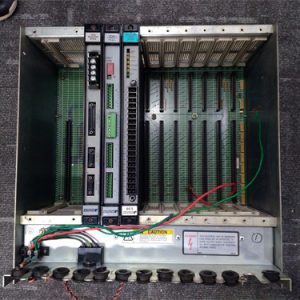

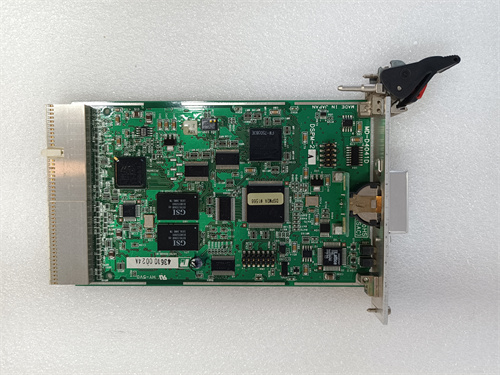

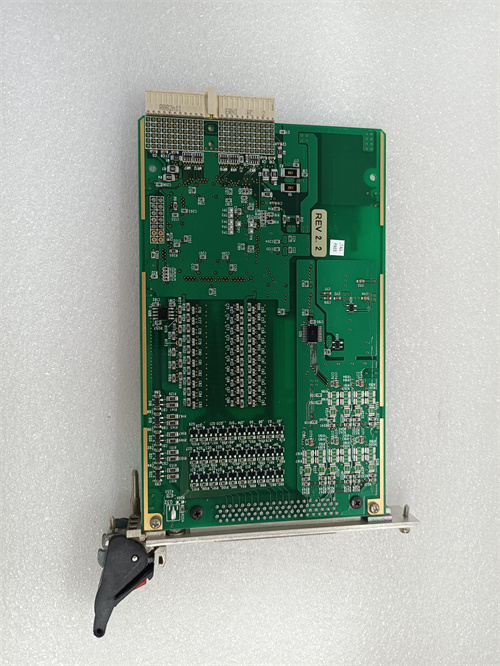

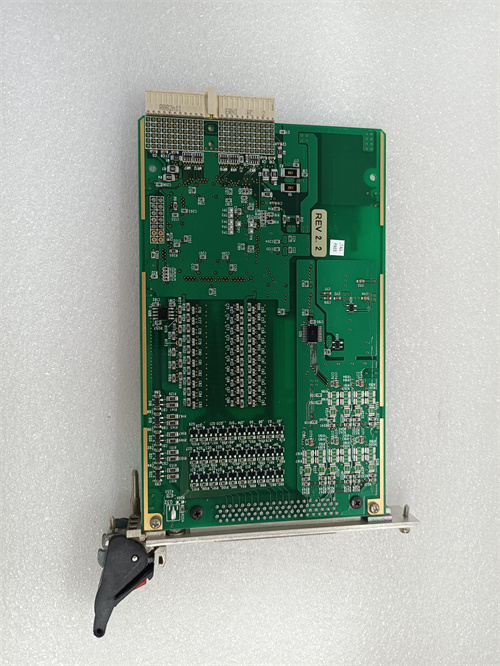

Product Name: RELIANCE DBU-400

Product Description

The RELIANCE DBU-400 is a high-performance programmable logic controller (PLC) designed to meet the diverse needs of industrial automation. This state-of-the-art device features a robust architecture that ensures reliability and efficiency in various applications. The RELIANCE DBU-400 combines exceptional processing power with versatile communication capabilities, making it an ideal choice for managing complex automated systems.

Equipped with intuitive programming interfaces and extensive I/O support, the RELIANCE DBU-400 significantly enhances operational flexibility. Users can easily integrate this PLC into existing systems or deploy it in new installations, streamlining processes while maintaining high levels of accuracy and speed.

Product Parameters

- Input Voltage: 24V DC

- Input Type: Digital/Analog

- Output Type: Relay/Solid State

- I/O Capacity: Up to 256 points

- Communication Protocols: Modbus TCP/IP, Ethernet/IP, Profibus

- Operating Temperature: -10°C to 60°C

- Dimensions: 200mm x 150mm x 100mm

- Weight: 1.5 kg

Advantages and Features

The RELIANCE DBU-400 comes with several standout features and advantages that set it apart from competitors. These include:

- High Processing Speed: The PLC’s fast CPU allows for quick execution of control commands, enhancing overall system responsiveness.

- Scalability: Users can easily expand the system as needed without significant reconfiguration.

- User-Friendly Interface: The intuitive programming environment reduces the learning curve for new users.

- Versatile Communication Options: Supports various industrial communication protocols for seamless integration.

- Robust Construction: Designed for durability in harsh industrial environments, ensuring long-term reliability.

Application Fields and Use Cases

The RELIANCE DBU-400 is suitable for a wide range of applications across various industries, including:

- Manufacturing: Control of assembly lines, robotic arms, and conveyor systems.

- Water Treatment: Automation of water quality monitoring and treatment processes.

- Food and Beverage: Management of processing lines and packaging systems.

- Oil and Gas: Monitoring and control of drilling operations and pipeline systems.

Use Case Example

One notable application of the RELIANCE DBU-400 was in a large-scale manufacturing facility, where it was utilized to automate the entire production line. By integrating the RELIANCE DBU-400 PLC, the facility achieved a 30% increase in production efficiency, significantly reducing downtime and operational costs.

Competitor Comparison

When comparing the RELIANCE DBU-400 to similar products from competing brands, several distinct advantages are evident:

- Faster Processing Speed: Compared to brand X’s PLC, the RELIANCE DBU-400 outperforms in execution time, resulting in quicker control responses.

- Better Communication Options: While competitors may offer limited communication protocols, the RELIANCE DBU-400 provides a wider range of compatibility, making it easier to integrate into existing systems.

- User-Friendly Software: Many users find the programming environment of RELIANCE DBU-400 more accessible and easier to navigate compared to alternatives.

Selection Recommendations

When choosing the RELIANCE DBU-400, consider the following factors:

- Application Requirements: Evaluate the specific needs of your automation project to ensure the RELIANCE DBU-400 meets all operational demands.

- Scalability Needs: Assess whether future expansions will be needed and confirm that the selected PLC supports this growth.

- Communication Needs: Verify the necessary communication protocols to ensure compatibility with existing systems.

Precautions

While using the RELIANCE DBU-400, it’s essential to follow certain precautions:

- Voltage Specifications: Always adhere to the specified input voltage to prevent damage.

- Environmental Conditions: Ensure the operating environment remains within the specified temperature range for optimal performance.

- Regular Maintenance: Conduct regular checks and updates to maintain system integrity and performance.

We are your trusted partner, offering the RELIANCE DBU-400 and other automation spare parts along with sales and technical support. We provide special discount prices. Please contact us, and we will be at your service.

RELIANCE+DBU-400

| 5STP08F6500 ABB PLC |

| ABB TV907-800-26 PLC |

| DS6000-02A ABB CPU |

| ABB 5STP1842L0013 I/O |

| 5STP09D2001 ABB |

| 5STP09D2001 ABB PLC |

| ABB 5STP04D4000 |

| 5SDA1444F0005 PLC |

| d053-7100-02-c-n ABB PLC |

| ABB KPC5700-22 PLC |

| PM153 3BSE003644R1 ABB PLC |

| DAPI100 ABB PLC |

| ABB MB510 3BSE002540R1 PLC |

| ABB CI522A 3BSE018283R1 PLC |

| PM152 3BSE003643R1 ABB PLC |

| BB1503BSE003616R1 PLC |

| PM154 3BSE003645R1 PLC |

| ABB 3BSE003645R1 PLC |

| 3BHL000986P7000 PLC |

| TRICONEX 3511 PLC |

| NGPS-12C PLCI/O |

| DSSB-01C PLC |

| DSQC679 ABB PLC |

| DSCS140 ABB PLC |

| DSAI145 ABB PLC |

| ABB DSAI110 PLC |

| DSAO110 DCS |

| ABB FS450R12KE3/AGDR-71C PLC |

| SDCS-CON-4 ABB DCS |

| SDCS-CON-1 ABB PLC |

| ABB 0VP-01 DCS |

| SDCS-IOB-21 ABB PLC |

Email: sales@plcfcs.com

Phone:+86 15343416922

Wechat:+86 15343416922

PLC : Allen Bradley , Siemens MOORE, GE FANUC , Schneider

DCS : ABB ,Honeywell, Invensys Triconex , Foxboro , Ovation,YOKOGAWA, Woodword, HIMA

TSI : Triconex , HIMA , Bently Nevada , ICS Triplex

Complete service we offer

Payment: T/T

Delivery: 1-2 days

Shipment: DHL UPS FedEx, etc

After-sales service: Yes, 24/7 hours

Email: sales@plcfcs.com

Email: sales@plcfcs.com Phone / Wechat:+86 15343416922

Phone / Wechat:+86 15343416922

Wechat:+86 15343416922

Wechat:+86 15343416922