Description

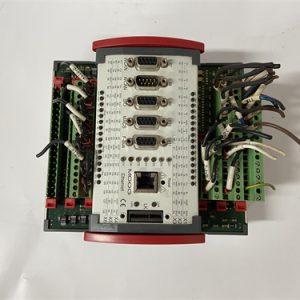

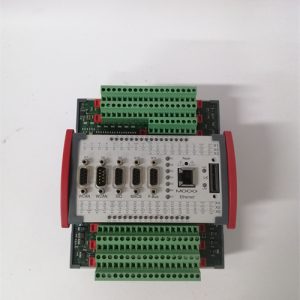

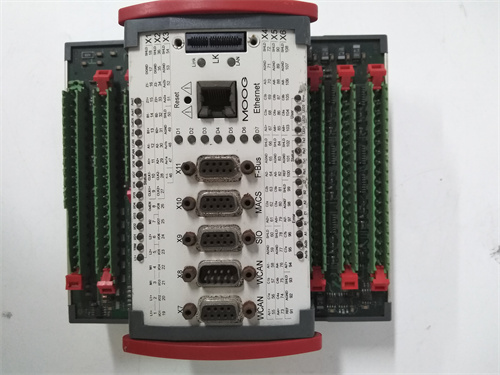

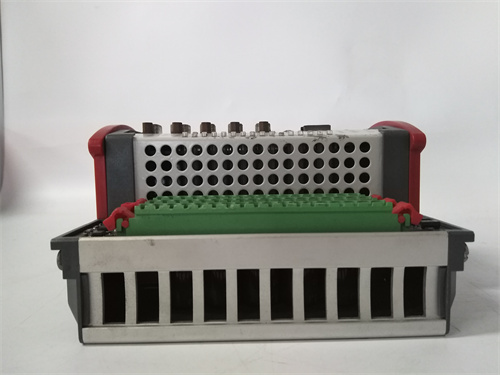

MOOG D136-001-007 D136-001-008

Product Description

The MOOG D136-001-007 and D136-001-008 are precision motion control systems, typically used for automation applications requiring high accuracy and reliability. These models are designed and manufactured by MOOG, a leader in the field of motion control technology. MOOG’s D136-001-007 and D136-001-008 offer advanced features, making them ideal for high-end automation systems where dynamic control, smooth operation, and long-term durability are essential.

These products are specifically built for use in industries such as aerospace, automotive, and industrial automation, where performance and precision are critical. Whether employed in motion control for robotics or as part of larger automated manufacturing systems, the D136-001-007 and D136-001-008 modules ensure superior functionality, long-term reliability, and ease of integration into existing control systems.

The MOOG D136-001-007 and D136-001-008 modules are designed to operate seamlessly within precision control systems, providing excellent feedback and control responses for critical applications. Their versatility, combined with robust features, ensures that they continue to operate efficiently and reliably in harsh industrial environments.

Product Parameters

- Input Voltage: 24 VDC

- Control Type: Closed-loop control

- Signal Type: Analog and digital signals

- Control Interface: RS-232 / RS-485 communication

- Operational Temperature Range: -20°C to +70°C

- Current Rating: 5-10 A

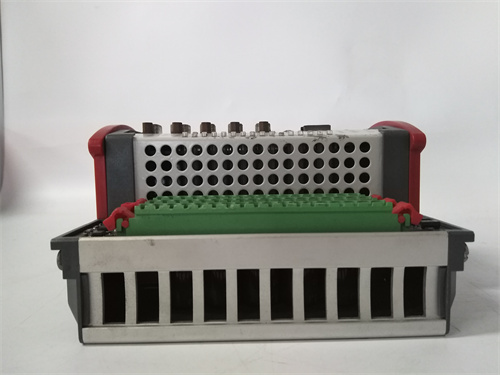

- Dimensions: 180 mm x 130 mm x 100 mm

- Weight: 1.2 kg

- Mounting Type: Panel mount, rack mountable

- Feedback Type: Encoder-based feedback

- Protection: Overload protection, short-circuit protection

Advantages and Features

-

High Precision Motion Control: The MOOG D136-001-007 and D136-001-008 are designed to deliver high precision and accuracy in motion control tasks. They provide exceptional control performance, which is crucial for systems where minute adjustments are required in real-time operations.

-

Wide Compatibility: These modules support both analog and digital control signals, allowing them to be integrated into a variety of existing control systems. This makes them versatile for use in different industrial environments.

-

Robust Protection Features: The MOOG D136-001-007 and D136-001-008 offer built-in protection features, such as overload and short-circuit protection, ensuring that the systems remain secure and operational even under extreme conditions.

-

Advanced Feedback Mechanisms: These models are equipped with encoder-based feedback systems, ensuring accurate real-time adjustments, minimizing lag, and enhancing the overall system performance.

-

Durability: With an operational temperature range of -20°C to +70°C, the MOOG D136-001-007 and D136-001-008 are designed to perform in harsh environments, ensuring long-lasting performance even in demanding industrial settings.

-

Scalability and Integration: The MOOG D136-001-007 and D136-001-008 are built to integrate seamlessly with other components in automation systems, making them highly scalable. As a result, they are an ideal solution for industries requiring system expansion or upgrades.

Applications and Use Cases

The MOOG D136-001-007 and D136-001-008 are widely utilized across multiple industries where motion control, precision, and reliability are essential:

-

Aerospace Industry: These models are frequently used in aerospace applications, including flight control systems, satellite positioning systems, and robotic arms. Their high precision and reliability make them perfect for these high-stakes environments.

-

Automated Manufacturing: In manufacturing, the MOOG D136-001-007 and D136-001-008 can be integrated into automated assembly lines, handling tasks such as pick-and-place, sorting, and machine-tool control.

-

Robotics: Whether for industrial robots or autonomous mobile robots, these motion control modules ensure that robotic arms and systems respond quickly and precisely, improving manufacturing flexibility and automation efficiency.

-

Test Equipment: The MOOG D136-001-007 and D136-001-008 are often used in specialized test rigs that require precise motion control for component testing, such as vibration testing, load testing, and calibration of other precision instruments.

-

Medical Equipment: In medical robotics, the precision offered by MOOG D136-001-007 and D136-001-008 allows for accurate movement in robotic surgery systems, diagnostic equipment, and therapeutic devices.

Competitive Product Comparison

In comparison to other motion control systems from brands like Parker Hannifin and Siemens, the MOOG D136-001-007 and D136-001-008 stand out for several reasons:

-

Superior Precision: While Parker and Siemens offer competitive motion control systems, the MOOG D136-001-007 and D136-001-008 are specifically known for their advanced control algorithms that deliver superior precision, making them ideal for high-accuracy applications.

-

Reliability and Durability: The built-in overload and short-circuit protection in the MOOG D136-001-007 and D136-001-008 make them highly reliable, even in harsh environments. Many competing products may not have this level of integrated protection.

-

Feedback System: The encoder-based feedback system used by the MOOG D136-001-007 and D136-001-008 allows for highly responsive and accurate control, which may not be as fast or accurate in competing products from other manufacturers.

-

Temperature Tolerance: The operational temperature range of the MOOG D136-001-007 and D136-001-008 (-20°C to +70°C) is wider than that of many competitive products, making them more suitable for industrial environments with extreme temperature fluctuations.

Selection Advice

When selecting between the MOOG D136-001-007 and D136-001-008 and competing motion control systems, consider the following factors:

-

Precision Needs: If your application demands extremely high precision and responsiveness, the MOOG D136-001-007 and D136-001-008 are highly recommended due to their superior motion control capabilities.

-

Environmental Conditions: If your system will be operating in extreme environments, the extended temperature range and robust protection features of the MOOG D136-001-007 and D136-001-008 make them ideal choices for harsh industrial settings.

-

Integration and Scalability: The flexibility and ease of integration of the MOOG D136-001-007 and D136-001-008 ensure that they will seamlessly fit into a variety of automation systems. If future expansion of your system is a concern, this scalability is an important factor.

-

System Compatibility: Ensure that the MOOG D136-001-007 and D136-001-008 modules are compatible with your existing control system. They support both analog and digital signals, as well as RS-232 and RS-485 communication protocols, making them versatile for a wide range of applications.

-

Budget Considerations: While the MOOG D136-001-007 and D136-001-008 may come at a higher initial cost compared to some competitors, their long-term reliability, accuracy, and advanced features provide excellent value for high-precision applications.

Important Considerations

-

Proper Installation: Make sure that the MOOG D136-001-007 and D136-001-008 are installed correctly within your automation system. Improper installation can lead to system failures or performance degradation.

-

Maintenance: Regular maintenance is essential to ensure that the MOOG D136-001-007 and D136-001-008 continue to operate optimally. Keep an eye on any wear components and periodically check for system updates.

-

Technical Support: Should you encounter any issues, MOOG offers exceptional technical support to ensure smooth operation. Don’t hesitate to reach out to their support team if needed.

-

Firmware Updates: Ensure that the firmware of the MOOG D136-001-007 and D136-001-008 is up-to-date for maximum performance and compatibility with the latest system integrations.

We are your trusted partner, providing sales and technical support for the MOOG D136-001-007 and D136-001-008 and other automation spare parts. We offer special discount prices and are ready to assist with all your needs. Please contact us, and we will be happy to serve you!

MOOG+D136-001-007 D136-001-008

| ABB 0VP-01 DCS |

| SDCS-IOB-21 ABB PLC |

| ABB SDCS-CON-3-A DCS |

| SNAT 602 TAC PLCCPU |

| YPK112A ABB PLC |

| YXT 121A YT223001-AC PLC |

| YXT 121A PLC |

| YXU 156B PLC |

| ABB SNAT 602 IAC |

| GM5001 ABB PLC |

| Yxu 156B YT223001-AE PLC |

| ABB DCS502-0075-41-1100000 PLC |

| YPP110A ABB |

| ABB DSTA170 57120001-FC PLC |

| 3ADT209019R0001 PLC |

| ABB SDCS-FIS-3A/31 PLC |

| OMD800E480C ABB PLC |

| CI810V1 ABB PLC |

| ABB 3BSE008584R1 PLC |

| 3BSE003828R1 ABB |

| ABB CI532V03 PLC |

| 3BSE002540R1 ABB PLC |

| DSDX452 ABB PLC |

| MCX913-5-5-1 PLC |

| DSTD108 57160001-ABD ABB PLC |

| DSTDW113 57160001-ZL ABB PLC |

| ABB DSTDW130 57160001-YX PLC |

| 3ASC25H705 ABB PLC |

| DATX133 ABB PLC |

| 3ASC25H219B ABB I/O |

| DATX100 ABB PLC |

| 3ASC25H208 DCS |

| A0FC-02 PLC |

| 3BSE050090R65 PLC |

Email: sales@plcfcs.com

Phone:+86 15343416922

Wechat:+86 15343416922

PLC : Allen Bradley , Siemens MOORE, GE FANUC , Schneider

DCS : ABB ,Honeywell, Invensys Triconex , Foxboro , Ovation,YOKOGAWA, Woodword, HIMA

TSI : Triconex , HIMA , Bently Nevada , ICS Triplex

Complete service we offer

Payment: T/T

Delivery: 1-2 days

Shipment: DHL UPS FedEx, etc

After-sales service: Yes, 24/7 hours

Email: sales@plcfcs.com

Email: sales@plcfcs.com Phone / Wechat:+86 15343416922

Phone / Wechat:+86 15343416922

Wechat:+86 15343416922

Wechat:+86 15343416922