Description

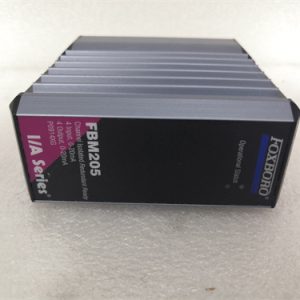

The FOXBORO+FBM237 is an I/O module designed for use in distributed control systems (DCS), particularly in industrial process control environments.

Product Name:

- FOXBORO+FBM237 Module

This is a Fieldbus Interface Module (FBM) used to connect field devices with a control system, allowing for reliable and real-time data communication.

Product Description:

The FBM237 is a Fieldbus Module that integrates seamlessly into the Foxboro I/A Series control system. It provides an interface between the Fieldbus network (such as HART, Foundation Fieldbus, or Profibus) and the control system. This allows for the collection of process data from remote field devices, such as smart transmitters, valves, positioners, and actuators, which communicate via a fieldbus protocol.

The FBM237 is typically used in environments where high reliability, accurate data transfer, and robust control systems are critical, such as in chemical, oil & gas, power generation, water treatment, and refining industries.

Product Parameters & Specifications:

- Type: Fieldbus Interface Module (FBM)

- Bus Protocol: Supports various protocols like HART, Foundation Fieldbus, and Profibus

- I/O Channels: Can typically handle up to 12 field devices per module, depending on configuration.

- Communication Speed: Typically operates at 31.25 kbit/s (Foundation Fieldbus), depending on the fieldbus type.

- Voltage: The module operates within a voltage range of 24 V DC (standard for industrial systems).

- Temperature Range: Typically rated for industrial operating environments, from -20°C to +60°C (-4°F to 140°F).

- Dimensions: Standard dimensions to fit into Foxboro I/A Series cabinets and control enclosures.

- Mounting: Designed for easy mounting in rack-based systems or control panel enclosures.

Product Use:

- Field Device Communication: Interfacing with various types of field devices in a process control system.

- Data Acquisition: Gathering real-time data from field sensors and devices, such as temperature, pressure, flow, level, and position.

- Control System Integration: Enabling communication between field devices and the main distributed control system (DCS), ensuring reliable process control and monitoring.

- Automation: Key component in automation systems, enabling precise control and feedback loops between the control system and field equipment.

- Process Monitoring and Control: Used in industries like chemical processing, oil and gas, pharmaceuticals, and energy to manage and monitor critical processes.

Key Features:

- Advanced Diagnostics: Provides diagnostic information to detect device and communication failures, helping to ensure high reliability and uptime.

- Modular Design: Can be configured and expanded based on the needs of the system.

- Supports Multiple Protocols: Flexible communication options make it adaptable to various industrial communication standards.

- Seamless Integration: Works well within the Foxboro I/A Series systems, offering easy integration with the existing infrastructure.

FOXBORO+FBM237

| ABB PM866K02-eA PLC |

| ABB 3BSE050199R2 PLC |

| PM864AK01-eA ABB PLC |

| 3BSE018161R2 ABB PLC |

| ABB PM864AK01-eA PLC |

| ABB PM860AK01-eA PLC |

| 3BSE066495R2 ABB PLC |

| PM860AK01-eA PLC |

| ABB CI854AK01-eA PLC |

| 3BSE030220R2 PLC |

| ABB PM864AK02-eA PLC |

| 3BSE018164R2 CPU |

| PM851AK01-eA I/O |

| 3BSE066485R2 I/O |

| CI867K01-eA ABB PLC |

| 3BSE043660R2 ABB PLC |

| PM866K01-eA ABB PLC |

| 3BSE0501 ABB PLC |

| 3BSE050198R2 PLC |

| PM856AK01-eA PLC |

| ABB 3BSE066490R2 PLC |

| ABB PM856AK01-eA PLC |

| PM861AK02-eA ABB |

| 3BSE018160R2 PLC |

| PM861AK01-eA ABB |

| ABB 3BSE018157R2 |

| PM861AK01-eA ABB |

| ABB MB801V512 |

| 3BSE042257R1 DCS |

| IB851 3BSC950194R1 ABB |

| 3BSC950194R1 ABB |

Email: sales@plcfcs.com

Phone:+86 15343416922

Wechat:+86 15343416922

PLC : Allen Bradley , Siemens MOORE, GE FANUC , Schneider

DCS : ABB ,Honeywell, Invensys Triconex , Foxboro , Ovation,YOKOGAWA, Woodword, HIMA

TSI : Triconex , HIMA , Bently Nevada , ICS Triplex

Complete service we offer

Payment: T/T

Delivery: 1-2 days

Shipment: DHL UPS FedEx, etc

After-sales service: Yes, 24/7 hours

Email: sales@plcfcs.com

Email: sales@plcfcs.com Phone / Wechat:+86 15343416922

Phone / Wechat:+86 15343416922

Wechat:+86 15343416922

Wechat:+86 15343416922