Description

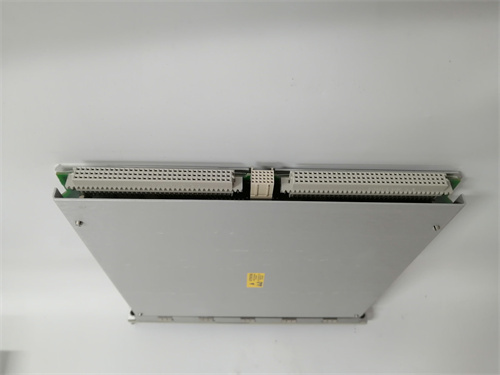

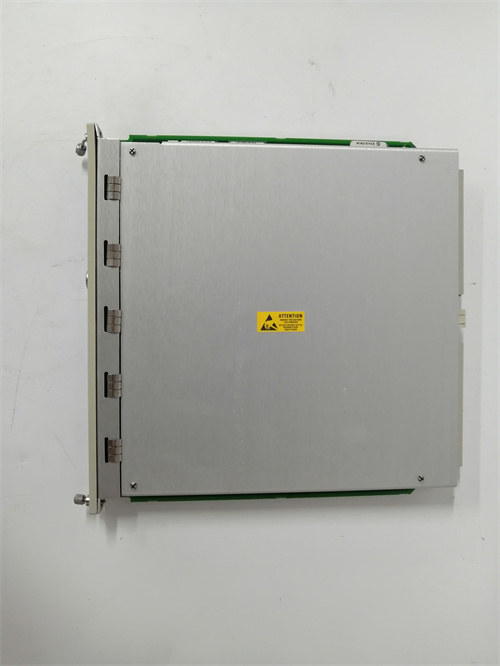

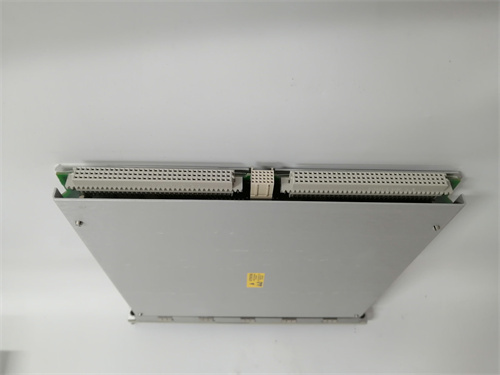

BENTLY+3500/22M, 3500/25, 3500/20 – Overview

The BENTLY+3500/22M, 3500/25, and 3500/20 are highly reliable and advanced monitoring and protection systems used in industrial automation and process control. These models from Bently Nevada (a part of Baker Hughes) are designed to ensure the safety and operational efficiency of critical machinery and equipment in various industrial sectors.

Product Description

The BENTLY+3500/22M is a key component of the 3500 series, focusing on vibration monitoring. This model provides comprehensive data collection, diagnostics, and analysis for machines such as turbines, compressors, and motors. The 3500/25 is a machinery protection system that integrates seamlessly with the 3500 series, offering real-time monitoring of equipment conditions. The 3500/20, on the other hand, is tailored for monitoring and protecting critical assets such as rotating machinery, ensuring high operational reliability.

All three models leverage Bently Nevada’s advanced technology, offering a robust platform for real-time data acquisition, advanced diagnostics, and machine protection, making them ideal for industries that require high-performance reliability, such as oil and gas, power generation, and heavy industrial applications.

Product Parameters

-

BENTLY+3500/22M:

- Vibration Transducer Input

- Real-time monitoring with advanced diagnostics

- Supports multiple vibration sensor types (prox, eddy current)

- High-frequency data acquisition

- Suitable for critical machinery applications

-

3500/25:

- Supports dynamic pressure, position, and other critical sensor inputs

- Built-in alarming and protection logic

- Real-time monitoring and alarming for machinery protection

- Adjustable alarm and trip points

- Includes robust communication protocols for integration with other systems

-

3500/20:

- Integrated vibration and temperature monitoring

- High-speed data logging and storage

- Digital and analog output options

- Compatible with a variety of sensors for broad application use

- Customizable alarm thresholds for machine protection

Advantages and Features

-

Real-time Monitoring and Diagnostics: The BENTLY+3500/22M, 3500/25, and 3500/20 all provide continuous real-time data and diagnostic tools for better machine health management. This minimizes unexpected downtime and costly repairs.

-

Advanced Protection Capabilities: These models are designed to monitor and protect critical equipment by detecting faults or abnormal conditions at an early stage, allowing for proactive maintenance.

-

High Scalability: These models can be scaled up easily, supporting a variety of sensor types and configurations, making them suitable for both small-scale operations and large industrial setups.

-

Integration with Other Systems: The models support a range of communication protocols, ensuring that they integrate seamlessly with other control systems, such as PLCs or SCADA systems, offering more comprehensive control and analysis.

-

Ease of Use: The 3500/25 and 3500/20 come with user-friendly interfaces, making setup and configuration easier and faster, even for users with limited experience.

-

Robust and Reliable: Designed for harsh industrial environments, these models are built with durable components that can withstand high temperatures, vibrations, and other challenging conditions.

Application Areas and Use Cases

The BENTLY+3500/22M, 3500/25, and 3500/20 are widely used in industries such as:

- Power Generation: Monitoring and protecting turbines, generators, and other critical power-generation equipment.

- Oil and Gas: Ensuring the safe and efficient operation of compressors, pumps, and other equipment used in extraction, refining, and distribution.

- Mining and Heavy Industry: Protecting heavy machinery such as crushers, mills, and conveyors from potential damage due to vibration or other faults.

- Chemical Processing: Protecting reactors, pumps, and other essential equipment from damage caused by mechanical failures.

Competitive Product Comparison

When compared to other machinery protection and monitoring systems, the BENTLY+3500/22M, 3500/25, and 3500/20 offer several advantages:

- Better Integration: Unlike many competitors, Bently Nevada models feature robust integration with existing PLC and SCADA systems, enhancing overall system flexibility.

- Real-time Analysis: The real-time diagnostic capabilities of these models far exceed many other offerings in the market, providing not just fault detection but also actionable insights into machine condition.

- Advanced Data Collection: While other systems may offer basic monitoring, the BENTLY+3500/22M and 3500/20 excel in gathering high-frequency data for more accurate diagnostics and predictive maintenance.

Selection Tips

-

Evaluate Equipment Type: Choose the BENTLY+3500/22M if your focus is primarily on vibration monitoring. For applications requiring broader dynamic protection, the 3500/25 and 3500/20 offer more comprehensive capabilities.

-

Integration Requirements: If your system needs to integrate with an existing control system (such as a PLC or SCADA), the 3500/25 and 3500/20 would be ideal due to their excellent compatibility with other industrial systems.

-

Environment: For environments with extreme conditions (high temperature, heavy vibration), these models are ideal due to their rugged design and durability.

-

Budget: While the 3500/25 is more feature-rich, the 3500/22M offers cost-effective vibration monitoring for basic machine health diagnostics.

Considerations

- Installation and Configuration: Professional setup may be required for optimal performance, particularly when integrating with other automation systems.

- Calibration: Regular calibration is essential for ensuring the accuracy and reliability of sensors and monitoring equipment.

- Maintenance: These models are low-maintenance, but regular software updates and hardware checks are recommended to ensure long-term operation.

We are your trusted partner, providing sales and technical support for the BENTLY+3500/22M, 3500/25, 3500/20, and other automation spare parts. We offer special discounted prices and are ready to assist you. Please contact us for more information and personalized service.

BENTLY+3500/22M 3500/25 3500/20

| PM154 3BSE003645R1 PLC |

| ABB 3BSE003645R1 PLC |

| 3BHL000986P7000 PLC |

| TRICONEX 3511 PLC |

| NGPS-12C PLCI/O |

| DSSB-01C PLC |

| DSQC679 ABB PLC |

| DSCS140 ABB PLC |

| DSAI145 ABB PLC |

| ABB DSAI110 PLC |

| DSAO110 DCS |

| ABB FS450R12KE3/AGDR-71C PLC |

| SDCS-CON-4 ABB DCS |

| SDCS-CON-1 ABB PLC |

| ABB 0VP-01 DCS |

| SDCS-IOB-21 ABB PLC |

| ABB SDCS-CON-3-A DCS |

| SNAT 602 TAC PLCCPU |

| YPK112A ABB PLC |

| YXT 121A YT223001-AC PLC |

| YXT 121A PLC |

| YXU 156B PLC |

| ABB SNAT 602 IAC |

| GM5001 ABB PLC |

| Yxu 156B YT223001-AE PLC |

| ABB DCS502-0075-41-1100000 PLC |

| YPP110A ABB |

| ABB DSTA170 57120001-FC PLC |

| 3ADT209019R0001 PLC |

| ABB SDCS-FIS-3A/31 PLC |

| OMD800E480C ABB PLC |

| CI810V1 ABB PLC |

Email: sales@plcfcs.com

Phone:+86 15343416922

Wechat:+86 15343416922

PLC : Allen Bradley , Siemens MOORE, GE FANUC , Schneider

DCS : ABB ,Honeywell, Invensys Triconex , Foxboro , Ovation,YOKOGAWA, Woodword, HIMA

TSI : Triconex , HIMA , Bently Nevada , ICS Triplex

Complete service we offer

Payment: T/T

Delivery: 1-2 days

Shipment: DHL UPS FedEx, etc

After-sales service: Yes, 24/7 hours

Email: sales@plcfcs.com

Email: sales@plcfcs.com Phone / Wechat:+86 15343416922

Phone / Wechat:+86 15343416922

Wechat:+86 15343416922

Wechat:+86 15343416922