Description

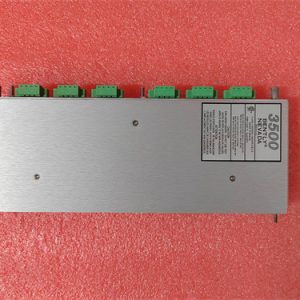

The Bently Nevada 3500/22M (part number 288055-01) is a part of the Bently Nevada 3500 Series Machinery Protection and Condition Monitoring System.

Product Name:

Bently Nevada 3500/22M – 288055-01

Product Description:

The Bently Nevada 3500/22M is a monitoring module designed to be used in the 3500 Series Machinery Protection System. This module is part of a broader system that offers condition monitoring and protection for critical machinery. It specifically serves to monitor and safeguard the machinery in real-time, allowing for early detection of potential faults or failures. This system provides both predictive maintenance insights and safety to prevent catastrophic machinery damage.

The 3500/22M module is specifically a Vibration Monitor module that processes vibration signals from accelerometers or velocity transducers to measure machinery health and detect anomalies.

Product Parameters and Specifications:

- Model Number: Bently Nevada 3500/22M, 288055-01

- Functionality:

- Vibration monitoring for rotating machinery (turbines, compressors, motors, etc.)

- Provides critical feedback on machine health.

- Works as part of a larger machinery protection system for fault detection.

- Measurement Type:

- Accelerometer Input (used for vibration signal processing).

- Velocity measurement (can also be used with velocity transducers).

- Signal Conditioning:

- Signal conditioning circuits for vibration transducers.

- Provides accurate, real-time monitoring data.

- Alarm and Trip Points:

- Configurable alarm set points for various machine conditions (excessive vibration, misalignment, imbalance, etc.).

- Trip outputs for emergency shutdown or corrective actions.

- Display and Monitoring:

- Can be integrated with the 3500 Series Rack for system-wide monitoring.

- Data logging for trend analysis and predictive maintenance.

- Input Range:

- Can accept input from various types of transducers, including 4-20 mA.

- Communication:

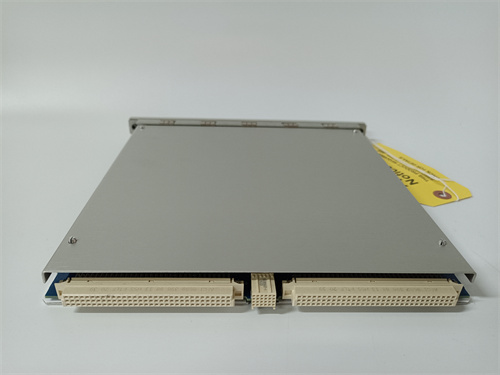

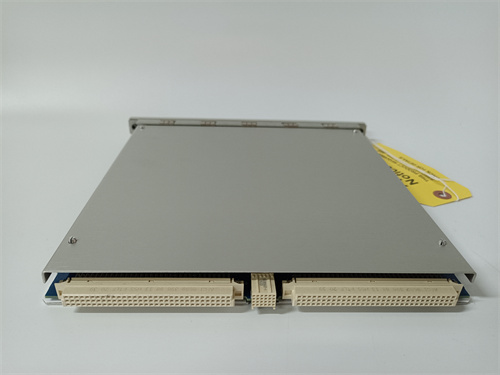

- Standardized communication interface to connect to the Bently Nevada 3500 rack system.

- Power Supply:

- Typically powered via the 3500 Rack system (with redundancy options for critical installations).

- Requires 24V DC power.

- Dimensions:

- 3U, 6.75-inch height.

- Operating Conditions:

- Operating Temperature: Typically 0 to 60°C.

- Humidity: 0-95% non-condensing.

- Altitude: Up to 2000 meters above sea level (with de-rating above this).

Product Use:

The 3500/22M module is used in machinery protection and condition monitoring systems across various industries, such as:

- Power generation plants

- Oil and gas facilities

- Chemical plants

- Pulp and paper mills

- Mining operations

- Industrial manufacturing facilities

- Marine and transportation sectors

Typical Applications:

- Vibration Monitoring: For rotating machinery such as pumps, turbines, motors, compressors, and fans.

- Condition Monitoring: Detects faults such as misalignment, imbalance, bearing wear, and cavitation.

- Predictive Maintenance: Used to monitor trends in vibration data and provide early warning signals to perform predictive maintenance and avoid unplanned shutdowns or catastrophic failures.

- Machinery Protection: Used to protect critical assets by triggering alarms or shutdowns when certain vibration thresholds are exceeded, reducing downtime and potential damage to equipment.

Key Benefits:

- Early Fault Detection: Helps identify emerging problems such as imbalance, misalignment, or bearing wear.

- System Integration: Integrates seamlessly with the larger 3500 Machinery Protection System, providing comprehensive protection and monitoring.

- Cost-Effective: Enables predictive maintenance, reducing the need for costly repairs or unplanned downtime.

- Reliability: Known for high reliability in harsh industrial environments.

BENTLY+3500/22M 288055-01

| ABB HIEE305106R0001 PLC |

| HIEE305069R1 ABB PLC |

| HIEE450880R1 ABB PLC |

| ABB HIEE400121R1 PLC |

| HIEE400643R1 ABB PLC |

| HIEE450824R1 ABB PLC |

| ABB HIEE400787R1 PLCPLC |

| ABB HIEE410103P1 PLC |

| HIEE305111R0001 ABB PLC |

| HIEE450932R1 ABB PLC |

| ABB HIEE401481R0001 PLC |

| HIEE300698R0001 ABB I/O |

| ABB HIEE205010R001 PLC |

| HIEE300888R0002 ABB PLC |

| ICSK20F1 ABB I/O |

| ABB 815-BOV169 |

| 1786-RPA ABB PLC |

| ABB 1786-RPFM PLC |

| 1747-L542 ABB PLC |

| 1747-L543 ABB DCS |

| ABB DAI03 PLC |

| ABB DAO01 PLC |

| ABB DAI04 |

| WT98 PLC |

| ABB 5STPO8F6500 PLC |

| 1MRB150083R1/E ABB CPU |

| ABB HESG441633R0001 I/O |

| HESG324258R3 ABB PLC |

| ABB HESG324015R1/K |

| ABB HIEE3007766R0001 PLC |

| ABB HESG324063R0100 |

| HESG324063R100/G ABB |

Email: sales@plcfcs.com

Phone:+86 15343416922

Wechat:+86 15343416922

PLC : Allen Bradley , Siemens MOORE, GE FANUC , Schneider

DCS : ABB ,Honeywell, Invensys Triconex , Foxboro , Ovation,YOKOGAWA, Woodword, HIMA

TSI : Triconex , HIMA , Bently Nevada , ICS Triplex

Complete service we offer

Payment: T/T

Delivery: 1-2 days

Shipment: DHL UPS FedEx, etc

After-sales service: Yes, 24/7 hours

Email: sales@plcfcs.com

Email: sales@plcfcs.com Phone / Wechat:+86 15343416922

Phone / Wechat:+86 15343416922

Wechat:+86 15343416922

Wechat:+86 15343416922