Description

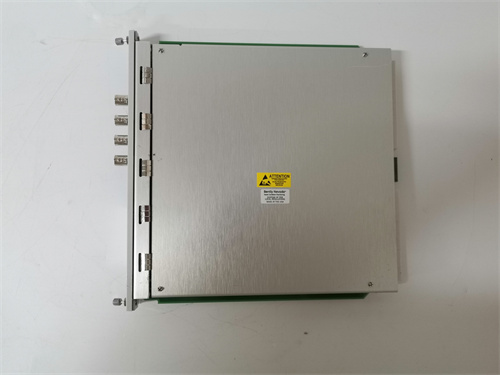

Product Name

BENTLY NEVADA 3500/40-01-CN

Product Description

The BENTLY NEVADA 3500/40-01-CN is an advanced monitoring system designed for machine condition monitoring and diagnostics. This model is part of the renowned BENTLY NEVADA 3500 system, known for its robust performance and reliability in critical applications. The 3500/40-01-CN specifically focuses on enhancements in vibration monitoring and provides comprehensive data analytics for predictive maintenance.

The BENTLY NEVADA 3500/40-01-CN features a modular design that allows for easy integration with existing systems. Its user-friendly interface and extensive connectivity options make it ideal for various industrial applications. The sophisticated algorithms embedded in the unit ensure precise monitoring of machine conditions, helping to identify potential issues before they escalate into major failures.

Product Specifications

- Model: 3500/40-01-CN

- Item Type: Vibration Monitor

- Power Supply: 90-250 VAC or 10-30 VDC

- Operating Temperature: -40 to +85 degrees Celsius

- Weight: Approximately 1.5 kg

- Dimensions: 15.2 x 10.2 x 4.4 cm

- Data Communication: Ethernet/IP, DeviceNet

- Standards Compliance: CE, UL, CUL

Advantages and Features

The BENTLY NEVADA 3500/40-01-CN offers numerous advantages, including:

- High Accuracy: Employs advanced signal processing techniques for precise vibration detection.

- Real-Time Monitoring: Provides continuous data on machine performance, enabling proactive maintenance actions.

- Scalability: Can be easily expanded by adding more modules, ensuring it meets the evolving needs of your facility.

- User-Friendly Interface: Simplifies monitoring and diagnostics through intuitive software tools.

- Robust Construction: Designed for operation in harsh industrial environments, ensuring longevity and reliability.

Application Fields and Use Cases

The BENTLY NEVADA 3500/40-01-CN is widely used in various industries, including:

- Oil and Gas: Monitoring critical rotating machinery in drilling and refining processes.

- Power Generation: Ensuring the health of turbines and generators to prevent downtime.

- Manufacturing: Keeping track of production machinery to reduce maintenance costs and improve uptime.

- Mining: Monitoring equipment to enhance operational efficiency and safety.

For example, in a recent case study in the oil extraction sector, a facility utilizing the BENTLY NEVADA 3500/40-01-CN was able to identify and address a potential failure in a gas compressor, saving the company significant costs associated with equipment downtime and repairs.

Competitive Comparison

When compared to other models in the market, such as Siemens SITRANS or Rockwell Automation’s Allen-Bradley series, the BENTLY NEVADA 3500/40-01-CN stands out due to its specialized focus on vibration monitoring and predictive analytics. While competitors may offer broader automation solutions, the depth of functionality and reliability in harsh environments makes the BENTLY NEVADA 3500/40-01-CN an invaluable tool for critical applications.

Selection Recommendations

When considering the BENTLY NEVADA 3500/40-01-CN, it is essential to evaluate:

- Specific Monitoring Needs: Assess whether vibration monitoring is a priority for your equipment.

- Integration Requirements: Determine compatibility with existing systems and the ease of installation.

- Budget Constraints: Evaluate the cost-effectiveness of implementing this monitoring solution versus potential downtime or failures.

- Support and Maintenance: Consider the availability of technical support and servicing options for the 3500/40-01-CN model.

Precautions

While deploying the BENTLY NEVADA 3500/40-01-CN, keep the following considerations in mind:

- Initial Calibration: Proper calibration after installation is crucial for accurate readings.

- Environmental Conditions: Ensure that the operating environment stays within specified limits to maintain device integrity.

- Regular Maintenance Checks: Schedule periodic testing and calibration to sustain performance levels.

- Data Management: Implement procedures for data analysis to effectively utilize the insights provided by the monitoring system.

We are your trusted partner, offering sales and technical support for BENTLY NEVADA 3500/40-01-CN and other automation spare parts. Contact us for special discount pricing and let us serve you with dedication.

BENTLY NEVADA+3500/40-01-CN

| ABB 3BSE003826R1 PLC |

| P-HC-BRC-10000000 ABB PLC |

| BRC-100 PLC |

| PM150V08 ABB |

| 3BSE009598R1 DCS |

| DSTD110A PLC |

| 57160001-TZ/1 PLC |

| ABB DSTA180 PLC |

| DSSA165 ABB PLC |

| REF615 PLC |

| 3BHE010751R0101 PLC |

| YPK113A ABB PLC |

| ABB DKH-E2201 PLC |

| PP30012HS ABB PLC |

| PM783F ABB I/O |

| 3BDH000364R0001 PLC |

| ABB PP836 PLC |

| 3BSE042237R1 ABB PLC |

| ABB CI522A PLC |

| 3BSE018283R1 PLC |

| 3BSE018333R1 I/O |

| DSSR122 ABB PLC |

| 48990001-NK PLC |

| XV371A PLC |

| PE1364B |

| ABB PCU-03 |

| DSTA160 ABB |

| ABB NTAC-02 dcs |

| 57520001-Z/1 |

| SAFT-188-I0C I/O |

| DSTA131 |

| 57120001-CV/1 |

| ABB SNAT601 |

| 07EA63R1 ABB |

| ABB DSTD132 |

| 57160001-FX/1 ABB |

| ABB DSSR170 |

| ABB DSSB146 DCS |

| 48980001-AP/2 ABB |

| ABB SDCS-FEX-32 |

| ABB SAMC 11 |

| SDCS-PIN-22+SDCS-PIR-21 ABB PLC |

| ABB T89120-E3087-H CPU |

| ABB 57520001-BK |

Email: sales@plcfcs.com

Phone:+86 15343416922

Wechat:+86 15343416922

PLC : Allen Bradley , Siemens MOORE, GE FANUC , Schneider

DCS : ABB ,Honeywell, Invensys Triconex , Foxboro , Ovation,YOKOGAWA, Woodword, HIMA

TSI : Triconex , HIMA , Bently Nevada , ICS Triplex

Complete service we offer

Payment: T/T

Delivery: 1-2 days

Shipment: DHL UPS FedEx, etc

After-sales service: Yes, 24/7 hours

Email: sales@plcfcs.com

Email: sales@plcfcs.com Phone / Wechat:+86 15343416922

Phone / Wechat:+86 15343416922

Wechat:+86 15343416922

Wechat:+86 15343416922