Description

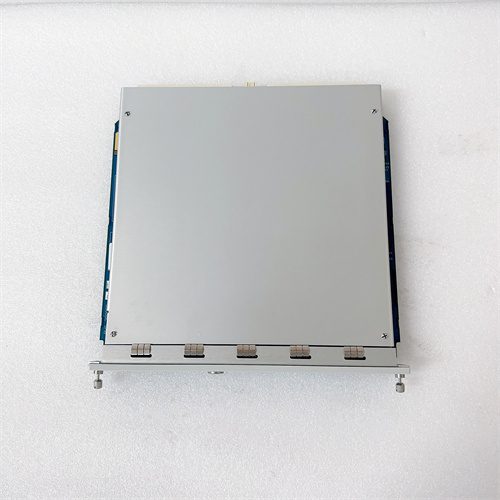

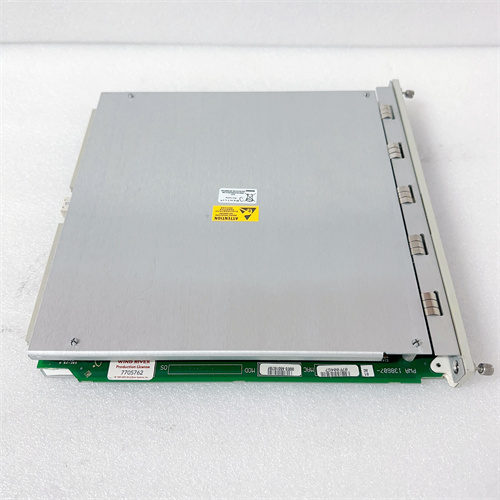

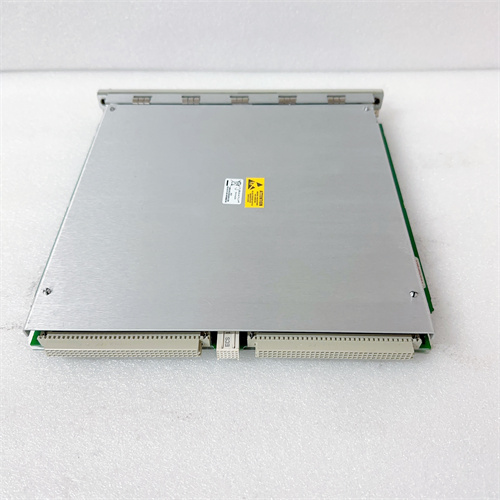

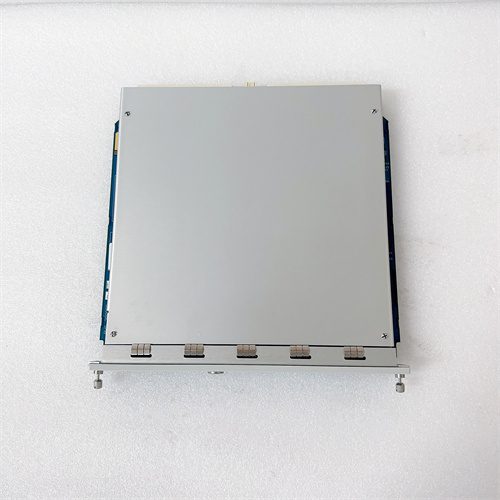

Product Name:

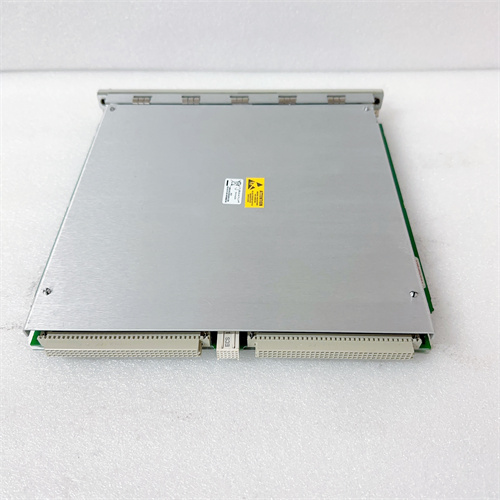

BENTLY NEVADA+3500/22-01-01-01

Product Description:

The BENTLY NEVADA+3500/22-01-01-01 is a high-performance vibration monitoring system designed for industrial applications. As part of the Bently Nevada 3500 series, it is primarily used for monitoring the health of machinery in real-time, ensuring operational reliability and minimizing downtime. The BENTLY NEVADA+3500/22-01-01-01 specifically features a dynamic data acquisition and analysis unit, which provides precise vibration measurements critical for the early detection of mechanical faults such as imbalance, misalignment, or bearing wear. This model includes a built-in redundancy feature, allowing for enhanced data security and continuous monitoring without interruption.

This equipment integrates seamlessly with Bently Nevada’s full range of monitoring solutions and is compatible with various industrial systems, ensuring that the BENTLY NEVADA+3500/22-01-01-01 can be incorporated into existing setups with ease.

Product Specifications:

- Part Number: BENTLY NEVADA+3500/22-01-01-01

- Vibration Measurement: Acceleration, velocity, and displacement inputs

- Frequency Range: 0.1 Hz to 5 kHz

- Power Input: 24V DC

- Output Signals: Analog and digital outputs

- Communication Protocols: Modbus, Ethernet, and serial communication support

- Monitoring Channels: Supports up to 8 channels per module

- Safety Standards: Complies with international safety and quality standards (CE, UL)

- Dimensions: 4.7 x 6.2 x 7.5 (12 cm x 15.7 cm x 19.1 cm)

- Temperature Range: -40°C to +70°C

Advantages and Features:

The BENTLY NEVADA+3500/22-01-01-01 offers numerous advantages, making it an ideal choice for vibration monitoring in critical machinery applications:

- High Accuracy: Offers precise vibration data collection, helping to detect even the smallest deviations that could indicate potential problems.

- Flexible Connectivity: Supports various communication protocols such as Modbus, Ethernet, and serial connections, ensuring compatibility with a wide range of industrial automation systems.

- Easy Integration: It is designed to integrate effortlessly with other Bently Nevada products, offering a complete condition monitoring solution.

- Robust Design: Built to withstand harsh industrial environments, ensuring reliable performance even in extreme conditions.

- Real-time Monitoring: Allows operators to monitor machinery health in real time, helping to reduce unplanned downtime.

Applications and Use Cases:

The BENTLY NEVADA+3500/22-01-01-01 is widely used in various industries for monitoring rotating machinery, such as:

- Power Generation: Monitoring turbines, motors, and pumps in power plants to ensure continuous operation.

- Oil and Gas: Used in offshore and onshore facilities for rotating equipment and compressor monitoring.

- Manufacturing: Applied to industrial machinery to detect vibration-related issues, ensuring minimal production delays.

- Mining: Helps monitor mining equipment like crushers, conveyors, and mills for early fault detection.

Application Case: In a large power plant, the BENTLY NEVADA+3500/22-01-01-01 is installed to monitor turbine health. The system’s real-time vibration data helps to detect imbalances and prevent catastrophic failure, ensuring smooth and efficient operation of the turbines.

Competitor Comparison:

When compared with other vibration monitoring systems, the BENTLY NEVADA+3500/22-01-01-01 stands out in several key areas:

- Reliability: While other brands offer similar monitoring solutions, Bently Nevada products are known for their unmatched reliability, which is critical in industries where failure costs are high.

- Scalability: The modular design of the BENTLY NEVADA+3500/22-01-01-01 allows for easy expansion as monitoring needs grow, something that competitors’ products often lack.

- Data Accuracy: Many competitors focus on basic vibration data, whereas the BENTLY NEVADA+3500/22-01-01-01 provides a more comprehensive analysis

BENTLY NEVADA+3500/22-01-01-01

| LDSYN-101 PLC |

| APOW-01C PLC |

| RAPI-01C PLC |

| LDSYN-101/3BHE005555R0101 ABB PLC |

| ABB APBU-44C PLC |

| NDBU-95C PLC |

| LDMUI-0 PLC |

| NETA-01 ABB |

| ABB AO810V2 |

| NAMC-51 ABB |

| 3BSE001449R1 ABB |

| ABB 5751017-E |

| ABB DSTC454 dcs |

| DSTC170 ABB dcs |

| 57520001-BK ABB |

| ABB IC520 3BSE001449R1 |

| DSTC454 5751017-E ABB PLC |

| ABB CI532V02 PLC |

| ABB DSTC170 57520001-BK PLC |

| NTCS04 ABB PLC |

| ABB SC300E PAC 031-1053-04 PLC |

| IMHSS03 dcsplc |

| HX-SLD702 ABB |

| ABB 07KT92 dcs |

| DSTX120 ABB DCS |

| SDCS-PIN-22 ABB PLC |

| SDCS-PIR-21 ABB PLC |

| ABB 57160001-MA/1 DCS |

| 07MK92 ABB I/O |

| ABB SAFT181 PLC |

| SAFT183 ABB PLC |

| ABB DLMO2 PLC |

| ABB NGDR-03C PLC |

| 07ZE61R302 ABB |

| ABB GJV3074321R302 PLC |

| PM632 PLC |

| 3BSE005831R1 ABB |

| ABB CS513 PLC |

| AI625 ABB |

| ABB 3BSE000435R1 DCS |

Email: sales@plcfcs.com

Phone:+86 15343416922

Wechat:+86 15343416922

PLC : Allen Bradley , Siemens MOORE, GE FANUC , Schneider

DCS : ABB ,Honeywell, Invensys Triconex , Foxboro , Ovation,YOKOGAWA, Woodword, HIMA

TSI : Triconex , HIMA , Bently Nevada , ICS Triplex

Complete service we offer

Payment: T/T

Delivery: 1-2 days

Shipment: DHL UPS FedEx, etc

After-sales service: Yes, 24/7 hours

Email: sales@plcfcs.com

Email: sales@plcfcs.com Phone / Wechat:+86 15343416922

Phone / Wechat:+86 15343416922

Wechat:+86 15343416922

Wechat:+86 15343416922