Description

Product Name

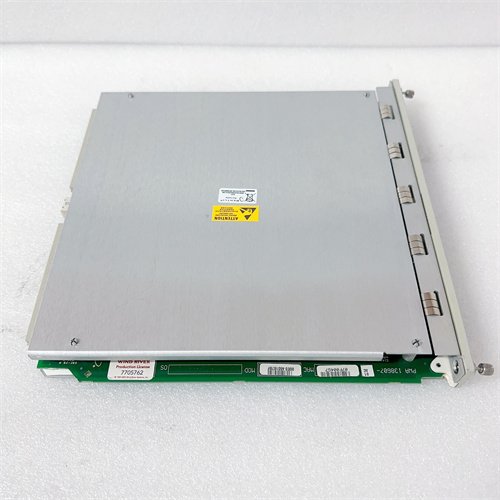

Bently Nevada 3500/15-05-05-00

Product Description

The Bently Nevada 3500/15-05-05-00 is a comprehensive monitoring solution designed to provide critical insights into the operational health of rotating machinery. Renowned for its reliability and precision, this model is part of a larger family of automation products by Bently Nevada, which is well-respected in the field of machinery condition monitoring. The 3500 series is distinguished by its ability to offer continuous monitoring for various parameters, aiding engineers and technicians in early detection of potential issues before they escalate into costly failures. This product specifically focuses on measuring vibration, which is essential for the predictive maintenance of industrial equipment.

Product Parameters

- Model Number: 3500/15-05-05-00

- Type: Machinery Condition Monitoring

- Measurement Range: Vibration measurement (displacement, velocity, and acceleration)

- Operating Temperature Range: -40°C to +70°C

- Power Supply: 24V DC

- Communication Protocols: Supports a variety of communication interfaces

- Weight: Approx. 1 kg

- Mounting Type: Standard mounting options available

Advantages and Features

The Bently Nevada 3500/15-05-05-00 offers several advantages that set it apart from its competitors. The key features include:

- High Reliability: Known for low failure rates and robust performance in harsh industrial environments.

- Scalability: Easily integrates into existing systems and can be scaled as per the monitoring requirements.

- Instant Alerts: Provides real-time notifications for abnormal conditions, thus enabling prompt action.

- User-friendly Interface: Simplifies setup and operation, reducing the learning curve for new users.

- Durable Design: Built to withstand extreme operating conditions, enhancing its longevity.

Application Fields and Case Studies

The Bently Nevada 3500/15-05-05-00 is primarily used across various sectors such as:

- Oil and Gas: Continuous monitoring of critical pumps and compressors, minimizing downtime.

- Manufacturing: Ensures the smooth operation of assembly lines by monitoring the health of benched machinery.

- Power Generation: Instrumental in monitoring turbines and generators, supporting efficient energy production.

- Marine: Ensures the reliability of machinery on vessels, contributing to safety and operational efficiency.

A notable application case is in a petrochemical plant where the implementation of the Bently Nevada 3500 series significantly lowered maintenance costs by proactively addressing machinery issues before they led to unexpected shutdowns, thus preserving productivity and safety.

Competitive Comparison

When compared to other competitors in the market, such as Siemens and Rockwell Automation, the Bently Nevada 3500/15-05-05-00 stands out in terms of specialized features for vibration monitoring. While other brands provide generalized machinery monitoring systems, Bently Nevada focuses on delivering precision-engineered sensors and software tailored for vibration analysis, giving it an edge in accuracy and reliability specifically for rotating equipment.

Selection Advice

When choosing a condition monitoring system, consider the size and complexity of your machinery. The Bently Nevada 3500/15-05-05-00 is ideal for industries where high reliability and real-time data are critical. It’s also recommended to assess the compatibility of the product with existing monitoring systems and the support offered by the supplier.

Precautions

Ensure proper installation and regular calibration of the Bently Nevada 3500/15-05-05-00 to maintain its accuracy. It’s advisable to refer to the operating manual for specific installation guidelines and conduct routine checks to avoid any unforeseen issues.

We are your trusted partner, providing both sales and technical support for Bently Nevada 3500/15-05-05-00 and other automation spare parts. Enjoy special discounted prices by contacting us; we are here to serve you diligently.

Bently Nevada+3500/15-05-05-00

| ABB 5STP06D2200 DCS |

| 5STP04D4600 ABB PLC |

| ABB 5STP12F4200 PLC |

| 5STP18F1401 ABB PLC |

| 5STP08F6500 ABB PLC |

| ABB TV907-800-26 PLC |

| DS6000-02A ABB CPU |

| ABB 5STP1842L0013 I/O |

| 5STP09D2001 ABB |

| 5STP09D2001 ABB PLC |

| ABB 5STP04D4000 |

| 5SDA1444F0005 PLC |

| d053-7100-02-c-n ABB PLC |

| ABB KPC5700-22 PLC |

| PM153 3BSE003644R1 ABB PLC |

| DAPI100 ABB PLC |

| ABB MB510 3BSE002540R1 PLC |

| ABB CI522A 3BSE018283R1 PLC |

| PM152 3BSE003643R1 ABB PLC |

| BB1503BSE003616R1 PLC |

| PM154 3BSE003645R1 PLC |

| ABB 3BSE003645R1 PLC |

| 3BHL000986P7000 PLC |

| TRICONEX 3511 PLC |

| NGPS-12C PLCI/O |

| DSSB-01C PLC |

| DSQC679 ABB PLC |

| DSCS140 ABB PLC |

| DSAI145 ABB PLC |

| ABB DSAI110 PLC |

| DSAO110 DCS |

| ABB FS450R12KE3/AGDR-71C PLC |

Email: sales@plcfcs.com

Phone:+86 15343416922

Wechat:+86 15343416922

PLC : Allen Bradley , Siemens MOORE, GE FANUC , Schneider

DCS : ABB ,Honeywell, Invensys Triconex , Foxboro , Ovation,YOKOGAWA, Woodword, HIMA

TSI : Triconex , HIMA , Bently Nevada , ICS Triplex

Complete service we offer

Payment: T/T

Delivery: 1-2 days

Shipment: DHL UPS FedEx, etc

After-sales service: Yes, 24/7 hours

Email: sales@plcfcs.com

Email: sales@plcfcs.com Phone / Wechat:+86 15343416922

Phone / Wechat:+86 15343416922

Wechat:+86 15343416922

Wechat:+86 15343416922