Product Name

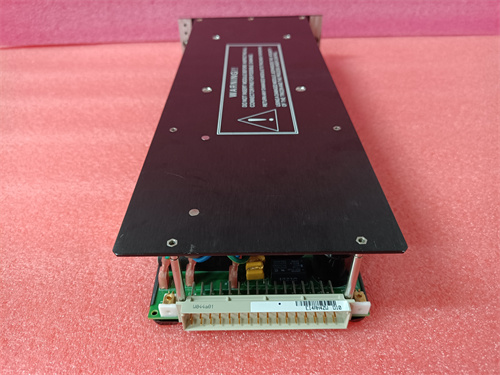

TRICONEX 8312

Product Description

The TRICONEX 8312 is a highly reliable and advanced PLC (Programmable Logic Controller) module designed for critical process applications. It is part of the renowned TRICONEX safety system, which is recognized for its robust architecture and exceptional performance in industries that require extreme levels of safety and reliability. The TRICONEX 8312 module ensures high availability and optimal performance in various automation applications, integrating seamlessly with existing networks and systems to enhance operational efficiency.

Product Specifications

- Input Voltage: 24V DC

- Output Capacity: 2 Amp Max per channel

- Temperature Range: -20°C to 70°C

- Communication Protocol: TRIPLEX Communication

- Dimension: 4.5 x 7 x 10 inches

- Weight: Approximately 1.5 kg

- Standards Compliance: SIL 3 (Safety Integrity Level 3)

Advantages and Features

The TRICONEX 8312 stands out due to its unparalleled safety features and high fault tolerance. Here are some key advantages:

- Redundant Configuration: The module can be configured in a redundant setup to ensure continuous operation even during component failures.

- High Reliability: Designed to operate in harsh environments, maintaining functionality in extreme conditions.

- Scalability: The modular design allows for easy expansion and integration within larger systems, accommodating future growth and additional functionalities.

- Real-Time Monitoring: Provides comprehensive monitoring and diagnostics, allowing for immediate anomaly detection and troubleshooting.

Application Fields and Case Studies

The TRICONEX 8312 is extensively used in various fields, including:

- Oil and Gas: Enhancing safety and control in drilling operations and refining processes.

- Chemical Processing: Managing critical operations requiring stringent safety standards and reliable automation.

- Power Generation: Supporting safety and control systems in nuclear and conventional power facilities.

For example, in a chemical processing plant, the TRICONEX 8312 was implemented to monitor reactor conditions, successfully preventing potential hazardous situations and ensuring compliance with industry safety regulations.

Competitive Comparison

When comparing the TRICONEX 8312 to other PLC modules from competitors:

- Honeywell Safety Manager: While reliable, it may not match the same level of redundancy and fault tolerance as the TRICONEX 8312.

- Siemens S7-1500: Although versatile, it lacks some of the advanced safety features that are inherently present in the TRICONEX 8312.

Selection Recommendations

When choosing the TRICONEX 8312, consider the following factors:

- Safety Requirements: Evaluate your operational needs in terms of safety standards and compliance.

- System Compatibility: Ensure the module is compatible with your existing PLC network and systems.

- Future Expansion: Assess whether the modular capabilities of the TRICONEX 8312 align with your future growth plans.

Precautions

While using the TRICONEX 8312, keep these precautions in mind:

- Regular Maintenance: Schedule periodic inspections and maintenance to detect any potential issues early.

- Environmental Considerations: Ensure the installation is in an environment within the specified operating conditions, avoiding extreme temperatures or humidity levels.

- Training of Personnel: Train your staff on proper handling and operation of the TRICONEX 8312 to maximize safety and efficiency.

We are your trusted partner, providing you with the best options for TRICONEX 8312 and other automation spare parts sales and technical support. You will receive special discounted prices. Please contact us, and we will be dedicated to serving you.

TRICONEX 8312