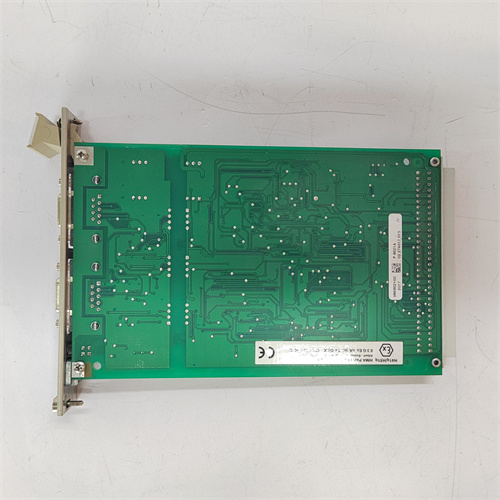

HIMA F8621A

Product Description

The HIMA F8621A is a state-of-the-art safety controller designed for high-reliability applications in process automation. This model is part of HIMA’s advanced safety solutions, offering robust functionality tailored for critical systems. The HIMA F8621A ensures compliance with international safety standards, making it an ideal choice for industries such as oil and gas, chemical processing, and manufacturing.

Product Parameters

- Supply Voltage: 24V DC

- Power Consumption: 5W

- Input Configuration: 16 digital inputs

- Output Configuration: 16 digital outputs

- Communication Protocols: Ethernet, Profibus, CANopen

- Certification: SIL 3, TÜV certified

- Operating Temperature: -20°C to +60°C

Advantages and Features

The HIMA F8621A stands out due to its modular architecture, allowing for easy configuration and scalability. Its multiple communication protocols facilitate integration into different systems effortlessly. Moreover, the high safety integrity level (SIL 3) ensures that the HIMA F8621A meets stringent safety requirements, enhancing operational reliability and reducing risks. The unit is also designed for high performance, capable of handling complex processes without compromising safety.

Application Areas and Case Studies

The HIMA F8621A is widely utilized in critical sectors, including:

- Oil and Gas: Implementing safety functions in drilling operations and refinery processes.

- Chemical Processing: Ensuring safe handling of hazardous materials and emergency shutdown systems.

- Manufacturing: Integrating safety controls in automated production lines.

A notable case study involves the deployment of the HIMA F8621A in a petrochemical plant, where it successfully minimized downtime during routine maintenance by allowing for seamless transitions between operational states while maintaining safety.

Competitive Comparison

When compared with competitors such as Siemens S7-1200 and Allen-Bradley ControlLogix, the HIMA F8621A offers superior safety features and a more versatile communication setup. It is particularly favored in industries demanding high safety levels, where other models may not provide the same degree of assurance.

Selection Recommendations

For businesses looking to implement safety systems, the HIMA F8621A is highly recommended for applications requiring stringent safety standards and complex automation capabilities. When choosing a model, consider factors such as the specific application requirements, the needed communication protocols, and the operational environment to ensure the best fit.

Cautions

While the HIMA F8621A is highly dependable, proper installation and configuration are crucial for optimal performance. Users should always refer to the manufacturer’s guidelines and seek professional assistance if needed. Regular maintenance checks are also recommended to ensure continued compliance with safety standards.

We are your trusted partner, offering sales and technical support for the HIMA F8621A and other automation spare parts. We provide special discount prices. Please contact us, and we will be dedicated to serving you.

HIMA F8621A

| DSSR116 ABB CPU |

| ABB DSPC172 CPU |

| DSSR120 ABB I/O |

| ABB DSPC172-2 PLC |

| DSSR121 ABB |

| ABB DSPC172H PLC |

| DSPC3001 ABB PLC |

| DSPC3121 ABB PLC |

| DSPC3122 ABB PLC |

| DSPC3221 ABB |

| ABB DSPC365 PLC |

| DSRB110 ABB PLC |

| DSRB310 ABB |

| ABB DSRF150 PLC |

| ABB DSRF180A PLC |

| DSRF180M ABB PLC |

| ABB DSRF182 PLC |

| DSRF182K13 ABB DCS |

| DSSB110 ABB CPU |

| DSSB120 PLC |

| DSSB140 ABB |

| DSSB145 ABB PLC |

| ABB DSPC170 PLC |

| DSPC170H ABB PLC |

| DSSS170 PLC |

| ABB DSTA-121A PLC |

| DSTA002 ABB PLC |

| ABB DSTA121 PLC |

| DSTA133I PLC ABB |

| DSTD155 ABB PLC |

| ABB DSTDN001 PLC |

| DSTK114 ABB PLC |

| DSTC121 ABB PLC |

| DSTK126 ABB PLC |

| ABB DSTC456 PLC |