The WOODWARD 8200-1312 controller is part of Woodward’s range of control systems designed for industrial applications, particularly in power generation, the oil and gas industry, and in various large machinery.

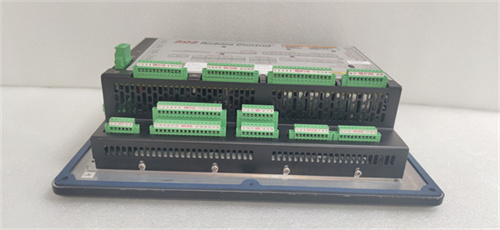

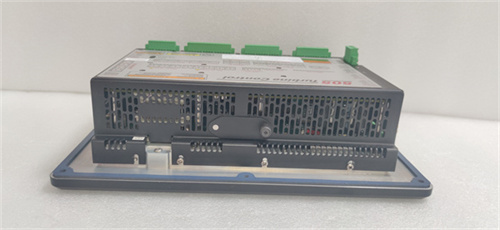

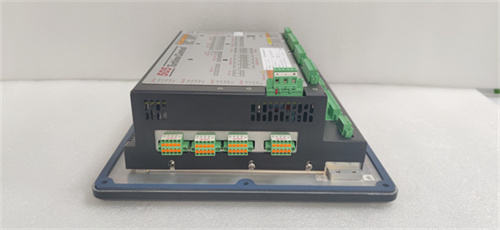

Product Name:

WOODWARD 8200-1312 Controller

Product Description:

The WOODWARD 8200-1312 is an advanced digital controller used for regulating various industrial processes. It is particularly designed to control turbines, engines, and other power generation equipment. This controller allows for precise control and monitoring of performance parameters, ensuring efficiency and reliability in operation.

Product Parameters and Specifications:

- Input Power Supply: Typically operates on a 24 VDC power supply.

- Input/Output:

- Multiple digital inputs for status and control signals

- Analog inputs for temperature, pressure, and other critical measurements

- Relay outputs for triggering alarms or indicating status

- Communication Interfaces:

- Can support multiple communication protocols including Ethernet, Modbus, CAN, etc.

- Temperature Range: Designed to operate in a wide temperature range, usually from -40°C to +85°C.

- Physical Dimensions: Varies, but typically a standard footprint suitable for industrial mounting.

- Mounting Options: Designed for panel or DIN rail mounting.

- Operating Environment: Typically IP-rated for dust and water resistance, suitable for harsh environments.

Product Use:

The WOODWARD 8200-1312 controller is commonly used in:

- Power Generation: To control gas and steam turbines, ensuring effective load management and stability.

- Oil and Gas Applications: For engine management in drilling equipment and compressors.

- Manufacturing Robotics: Providing real-time control for automated machinery.

- HVAC Systems: For managing large-scale climate control systems.

Key Features:

- Programmable Logic: Allows customization of control logic based on specific application needs.

- Real-Time Data Monitoring: Provides live data feedback for operational efficiency.

- User-Friendly Interface: Often features an intuitive display for ease of use and programming.

- Diagnostics and Troubleshooting Tools: Built-in capabilities for predictive maintenance and fault identification.

| IC693CP1350 CPU350 DCS |

| HE693THM884 DCS |

| GE IC693CPU341 |

| IC693ALG391 GE DCS |

| IC693MDL340 PLC |

| IC693ALG221 PLC |

| IC697CPU782 PLC |

| IC693Cmm311H PLC |

| AI625 DCS |

| IC697CP1781 PLCI/O |

| IC670MDL240 PLC |

| GE IC693CMM321 PLC |

| IC693ALG392 PLC |

| GE IC660EBD020 PLC |

| IC693PWR321 PLC |

| IC693PBM200 PLC |

| IC693MDL940 |

| GE IC693MDL753 PLC |

| GE IC693MDL753 |

| IC693MDL655 PLC |

| GE IC693CPU360 CPU |

| IC693ALG442 DCS |

| IC660TBD120A PLC |

| IC660BBD020Y PLC |

| IC200ERM002E PLC |